If you’ve ever held a piece of Fiesta dinnerware, you know there’s something special about its weight, its smooth glaze, and those impossibly vibrant colors.

But have you ever wondered how these iconic pieces are made? Since 1936, the Homer Laughlin China Company in Newell, West Virginia, has been crafting Fiesta dinnerware using a blend of traditional ceramic techniques and modern manufacturing innovation.

Understanding how Fiesta is made helps explain what makes Fiestaware so special, from its durability to its brilliant color palette.

Unlike mass-produced imported dinnerware, each piece of Fiesta goes through a carefully controlled manufacturing process that combines American craftsmanship with quality materials.

The result? Dinnerware that can last for generations while maintaining its vibrant appearance.

In this comprehensive guide, we’ll take you through the entire manufacturing journey from raw clay preparation to the final quality inspection, revealing the fascinating process behind America’s most beloved colorful dinnerware.

Homer Laughlin to Fiesta: The Evolution of an Icon

The story of Fiesta dinnerware begins with the Homer Laughlin China Company, founded in 1871 in East Liverpool, Ohio, before relocating to Newell, West Virginia.

For decades, Homer Laughlin produced traditional white china for American households.

However, in the midst of the Great Depression, the company recognized that Americans wanted something different, something bright, cheerful, and affordable.

In 1936, designer Frederick Hurten Rhead created Fiesta dinnerware, introducing a revolutionary concept: vibrant, mix-and-match colors in durable, everyday china.

The original five colors, red, cobalt blue, light green, yellow, and ivory, broke away from the formal white china tradition.

Fiesta’s Art Deco-inspired concentric rings and bold hues captured the optimistic spirit Americans craved during difficult economic times.

The line was discontinued in 1973, but public demand brought it back in 1986 with updated, lead-free glazes and new colors.

Today, Homer Laughlin continues the Fiesta legacy, producing millions of pieces annually while maintaining its commitment to American manufacturing.

This evolution from traditional china maker to colorful dinnerware icon represents one of American manufacturing’s most enduring success stories.

The Raw Materials: What Makes Fiesta Dinnerware

Clay Composition and Sourcing

Fiesta dinnerware begins with carefully selected raw materials. The body of each piece is made from a specific blend of natural clays, feldspar, and silica.

While the exact formula is proprietary, the clay body used for Fiesta is a type of earthenware that balances strength, workability, and the ability to accept vibrant glazes.

The primary ingredients include:

- Kaolin (China Clay): Provides whiteness and structural integrity

- Ball Clay: Adds plasticity and workability during forming

- Feldspar: Acts as a flux, helping ingredients fuse during firing

- Silica: Provides hardness and reduces shrinkage

These materials are sourced from various locations across the United States, ensuring consistency while supporting domestic suppliers.

The quality of these raw materials directly impacts the final product’s durability and appearance.

The Mixing Process

Once the raw materials arrive at the Homer Laughlin facility, they undergo a precise mixing process called “batching.”

Large industrial mixers combine the dry ingredients with water to create a uniform slip of a liquid clay mixture with a consistency similar to heavy cream.

This slip is then passed through magnetic separators to remove any iron particles that could cause discoloration or defects.

The slip is de-aired in a vacuum chamber to eliminate air bubbles that could cause cracks or weakness in the finished product.

After de-airing, the mixture is either used immediately for certain forming processes or dried to the proper moisture content for press forming.

This moisture content is critical, too wet and the pieces won’t hold their shape, too dry and they’ll crack during forming.

The Forming Process: Shaping Fiesta’s Iconic Designs

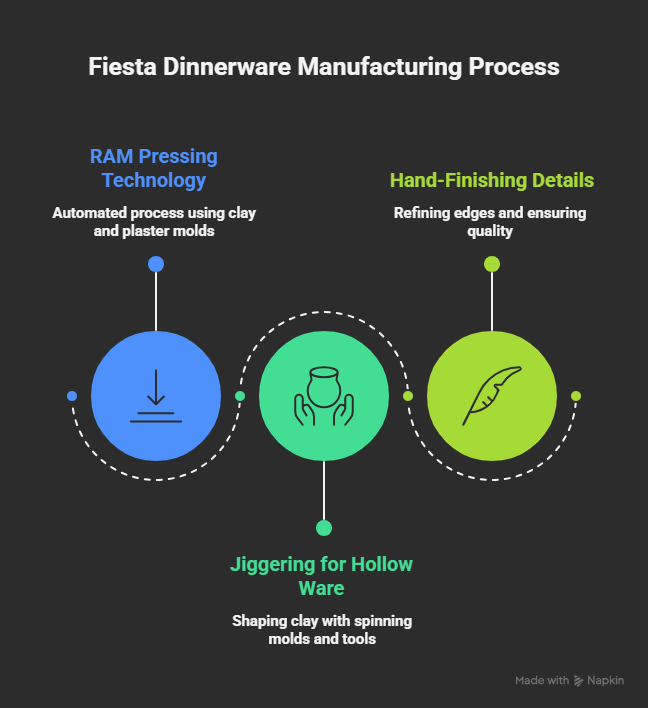

RAM Pressing Technology

The majority of Fiesta pieces—plates, saucers, and shallow bowls are formed using a technique called RAM pressing.

This automated process involves placing a measured amount of clay (called a “bat”) onto a plaster mold.

A hydraulic ram then presses a metal die down onto the clay, forcing it to conform to both the mold (which forms the top surface) and the die (which forms the bottom).

RAM pressing offers several advantages over traditional methods. It’s faster, more consistent, and produces pieces with uniform thickness and weight.

The pressure applied—often several tons—compacts the clay particles, creating a denser, stronger structure. For Fiesta’s signature plates with their distinctive concentric rings, RAM pressing ensures each ring is crisp and perfectly formed.

The process takes only seconds per piece, but precision is everything. The molds themselves are works of art, machined to exact specifications to ensure that every 10.5-inch dinner plate is identical to the thousands that came before it.

Jiggering for Hollow Ware

While RAM pressing works beautifully for flat pieces, hollow items like mugs, bowls, and pitchers require a different approach called jiggering or jolleying.

In this process, a ball of clay is placed on a spinning plaster mold. As the mold rotates, a shaped metal tool (the jigger) is brought down against the clay, forming the interior profile while the mold shapes the exterior.

For pieces like the iconic Fiesta mug, the body is jiggered while handles are separately formed and then attached by hand using liquid clay slip as an adhesive.

This attachment point is carefully smoothed by skilled workers—one of the few manual steps remaining in modern Fiesta production.

Hand-Finishing Details

Even with automated forming processes, human hands still play a crucial role. After forming, each piece goes through a fettling process where any rough edges, mold seams, or imperfections are carefully trimmed and smoothed.

Workers use specialized tools to refine edges, smooth attachment points, and ensure each piece meets quality standards before moving to the next stage.

This combination of machine precision and human attention to detail is part of what gives Fiesta its consistent quality while retaining the charm of handcrafted ceramics.

Drying: The Critical Waiting Period

Controlled Drying Rooms

After forming, Fiesta pieces enter temperature and humidity-controlled drying rooms.

This stage is more critical than it might seem. Dry too quickly, and pieces will crack or warp; too slowly, and production backs up.

The drying process typically takes 24 to 48 hours, depending on the size and thickness of the piece.

During drying, the clay releases moisture, shrinking by approximately 5-7%. This shrinkage is carefully calculated into the original mold designs, ensuring finished pieces meet exact size specifications.

The concentric rings on Fiesta plates can actually be more pronounced after drying as the clay contracts.

Larger pieces like serving bowls and pitchers require longer drying times and may be turned or repositioned during the process to ensure even moisture loss.

Rush this stage, and you’ll end up with cracked or warped pieces that must be discarded.

The First Fire: Bisque Firing

Into the Kiln

Once completely dry, pieces undergo their first firing, called bisque firing. Greenware (unfired, dried clay) is carefully loaded onto kiln cars, large movable platforms that travel through a tunnel kiln.

These tunnel kilns can be over 300 feet long, with different temperature zones.

The bisque firing process takes approximately 18-24 hours as pieces slowly travel through the kiln. Temperatures gradually increase to around 1,945°F (1,063°C).

This heat transforms the clay chemically and physically. Water molecules trapped within the clay structure are driven off permanently, and the clay particles begin to fuse through a process called sintering.

Why Bisque Fire?

You might wonder why Fiesta pieces are fired twice instead of once. The bisque firing creates a porous, chalk-like material that’s strong enough to handle but porous enough to absorb glaze.

This porosity is essential as it allows the colored glaze to adhere properly and evenly during the glazing process.

Bisque-fired pieces are inspected again at this stage. Any pieces with cracks, chips, or warping are rejected. Only pieces that meet strict standards proceed to the glazing department.

The Magic of Color: Glazing Fiesta Dinnerware

Fiesta’s Signature Glazes

The vibrant colors that make Fiesta instantly recognizable come from carefully formulated ceramic glazes.

Each color is a complex mixture of minerals, metal oxides, and glass-forming ingredients suspended in water.

The glaze chemistry determines not just the color but also the finish, durability, and food safety of the final product.

Fiesta’s glazes are lead-free (since the 1986 reintroduction) and meet all FDA standards for food contact surfaces. Different metal oxides create different colors:

- Cobalt oxide produces blues

- Chrome oxide creates greens

- Iron oxide yields reds and oranges

- Titanium and zinc create whites and yellows

The exact recipes are proprietary secrets, refined over decades to achieve Fiesta’s distinctive color palette.

What makes these glazes special is their opacity and vibrancy—they completely cover the bisque body beneath while maintaining brilliant color intensity.

The Glazing Process

Glazing at Homer Laughlin is a combination of automated and manual processes. Flat pieces like plates typically travel through a glazing booth where atomized glaze is sprayed evenly across the surface.

The bisque’s porosity draws the liquid into the surface, leaving a powdery coating that will melt into glass during the final firing.

Hollow pieces and more complex shapes may be dipped into large vats of glaze. Workers hold pieces by their foot or rim and quickly immerse them, ensuring complete, even coverage.

The glaze thickness is critical, too thin and the color will be weak or uneven; too thick and it may run or create an uneven surface during firing.

Certain areas where pieces will sit in the kiln are wiped clean of glaze. If glaze remains on the bottom of a plate or foot of a mug, it will melt and fuse the piece to the kiln shelf, ruining both the piece and the shelf.

Color Consistency Challenges

Maintaining consistent color across thousands of pieces is one of the most challenging aspects of ceramic production.

Slight variations in glaze thickness, firing temperature, or even humidity during application can affect the final color.

Homer Laughlin maintains rigorous quality control, mixing glaze batches to precise specifications and regularly testing fired samples against color standards.

This attention to detail explains why a Fiesta plate purchased today will match one bought five years ago—essential for customers building their collections over time.

Learn more about why Fiestaware is so expensive, and you’ll see how this quality control contributes to the value.

The Final Fire: Glost Firing

High-Temperature Transformation

The glost firing (also called glaze firing) is where Fiesta pieces achieve their final appearance.

Glazed pieces are carefully loaded onto kiln cars, with specialized stilts or supports preventing pieces from touching each other or the kiln shelves.

The kiln cars then travel through another tunnel kiln over approximately 16-20 hours.

Temperatures in the glost kiln reach approximately 2,100°F (1,149°C)—hot enough to melt the glaze into a smooth, glassy surface.

At these temperatures, the glaze ingredients fuse and bond permanently with the bisque body beneath.

The clay body itself undergoes further vitrification, becoming harder and less porous.

The Chemistry of Color Development

Here’s where the magic happens: as the glaze melts, the metal oxides react with other ingredients, developing their final colors.

Some colors are relatively stable throughout the firing, while others undergo dramatic changes.

The cobalt blue, for instance, looks black or gray in its unfired state but develops its brilliant blue only at peak temperature.

The kiln’s atmosphere also affects color development. Fiesta’s tunnel kilns carefully control oxygen levels throughout the firing cycle. Too much or too little oxygen can shift colors, creating unwanted variations.

Cooling Period

After reaching peak temperature, the kiln cars slowly move into cooling zones. Rapid cooling would cause thermal shock, cracking, or shattering the pieces.

The cooling process is carefully controlled over several hours, allowing the glaze and body to contract at compatible rates.

As pieces cool below approximately 1,000°F, the glaze solidifies from a molten liquid into a hard, glossy surface.

The result is Fiesta’s characteristic smooth, durable finish that’s resistant to scratching, staining, and fading.

Quality Control and Finishing

Rigorous Inspection Standards

Once cool enough to handle, every single piece of Fiesta undergoes inspection. Quality control workers examine each item for:

- Color consistency and coverage

- Surface defects (pinholes, crawling, crazing)

- Dimensional accuracy

- Warping or distortion

- Glaze defects (runs, thin spots, contamination)

Pieces are compared against master samples for each color. Any piece that doesn’t meet Homer Laughlin’s strict standards is rejected and recycled.

This rejection rate, while carefully managed, is part of ensuring that only the best pieces reach customers.

Final Finishing Touches

Approved pieces receive final finishing. The unglazed bottoms (where pieces sat during firing) are smoothed with abrasive belts to prevent scratching of table surfaces.

Workers check that the glaze hasn’t adhered to these areas during firing.

Certain specialty items receive additional hand-finishing. Fiesta’s serving pieces with lids, for example, are paired to ensure proper fit. Each lid is tested on its base, and only well-matched sets proceed to packaging.

Packaging for Protection

Fiesta pieces are carefully wrapped and packed for shipping. The packaging must protect these ceramic pieces during transit while presenting them attractively to retail customers.

Plates are typically wrapped individually and stacked; mugs and bowls are nested with protective material between each piece.

Before packaging, pieces receive a final visual inspection. This multi-stage quality control process—from greenware through final packaging—ensures the consistency and quality that Fiesta customers expect.

Why Fiesta Dinnerware is Still Made in the USA?

The Economics of Domestic Production

In an era when most dinnerware is imported, Fiesta’s continued American production is remarkable.

Homer Laughlin has maintained its manufacturing in Newell, West Virginia, for over a century, even as competitors moved production overseas. Several factors make this possible:

Automation and Efficiency: Modern equipment, including state-of-the-art tunnel kilns and automated forming machinery, keeps production costs competitive while maintaining quality standards that would be difficult to achieve with overseas production.

Vertical Integration: Homer Laughlin controls much of its supply chain, from raw material processing through final packaging. This integration reduces costs and ensures quality control at every stage.

Skilled Workforce: Generations of families have worked at the Newell facility, developing specialized skills that are difficult to replicate. This institutional knowledge contributes to consistent quality and innovation.

Quality and Brand Reputation

American manufacturing allows Homer Laughlin to maintain the quality standards that have made Fiesta a trusted brand for nearly 90 years.

When quality issues arise, they can be addressed immediately rather than waiting for overseas shipments. This responsiveness protects Fiesta’s reputation and customer satisfaction.

The “Made in USA” label also resonates with customers who value supporting American manufacturing and workers.

For many Fiesta buyers, knowing their dinnerware is made domestically is part of its appeal and justifies the premium over imported alternatives.

Environmental and Ethical Considerations

Domestic production reduces the environmental impact of international shipping.

While ceramics manufacturing is energy-intensive regardless of location, producing Fiesta in the United States means shorter supply chains and lower transportation emissions.

American production also ensures compliance with U.S. labor and environmental regulations.

Workers at Homer Laughlin receive competitive wages and benefits, and the facility must meet EPA standards for emissions and waste disposal factors that contribute to Fiesta’s overall value proposition.

Caring for Your Fiesta: Making the Manufacturing Investment Last

The effort and precision that go into manufacturing each piece of Fiesta make proper care important.

While the manufacturing process creates durable, chip-resistant dinnerware, following proper care guidelines ensures your Fiesta will last for decades.

Fiesta dinnerware is dishwasher-safe, microwave-safe, and oven-safe (except pieces with metallic accents), making it ideal for everyday use.

The high-fired glaze resists staining and scratching under normal use. However, avoiding thermal shock (extreme temperature changes) and using proper stacking techniques will maximize longevity.

For comprehensive guidance on maintaining your collection, check out our Fiesta dinnerware care and maintenance guide, which covers everything from daily use to long-term storage.

Conclusion: The Art and Science Behind Every Piece

Creating Fiesta dinnerware is a fascinating blend of industrial efficiency and artisanal craftsmanship.

From carefully mixing raw materials to the final quality inspection, each piece undergoes a journey measured in days and involving precise temperature control, skilled workers, and rigorous standards.

Understanding this manufacturing process reveals why Fiesta has remained America’s favorite colorful dinnerware for nearly 90 years.

The combination of quality materials, proven techniques, modern technology, and American craftsmanship produces dinnerware that’s both beautiful and built to last.

The next time you set your table with Fiesta’s vibrant colors, you’ll know the remarkable story behind each piece—from raw clay to the finished plate, carefully crafted in Newell, West Virginia, continuing a manufacturing tradition that began in 1936.

That’s the Fiesta difference: not just colorful dinnerware, but a piece of American manufacturing heritage on your table.

Whether you’re starting your collection or adding to an established set, every piece of Fiesta represents this careful balance of art, science, and tradition. It’s dinnerware designed for real life, made to last for generations, and proudly crafted in the USA.