Standing in the cookware aisle, you’re faced with a decision that affects more than just tonight’s dinner; it shapes your family’s health for years to come.

The comparison between ceramic vs stainless steel cookware isn’t merely about preferences; it’s about safety, performance, and the peace of mind that comes from knowing what touches your food.

With conflicting claims flooding the market, ceramic brands promising toxin-free cooking while stainless steel advocates tout unmatched durability, how do you separate marketing hype from kitchen reality?

This comprehensive guide cuts through the confusion, examining everything from chemical leaching risks to long-term cost efficiency.

Whether you’re a home chef or kitchen novice seeking healthier options or simply tired of replacing worn-out pans, understanding the real differences between these two popular cookware materials will transform how you equip your kitchen.

What Is Ceramic Cookware?

Ceramic cookware has surged in popularity as consumers seek alternatives to traditional non-stick options.

However, understanding what “ceramic” actually means in the cookware context is essential for making informed decisions about ceramic vs stainless steel safety.

Pure ceramic vs ceramic-coated (aluminum base)

True ceramic cookware comes in two distinct forms.

Pure ceramic pieces are made entirely from clay hardened at high temperatures, creating naturally non-stick surfaces without any metal base.

These are relatively rare and expensive. Most products marketed as ceramic cookware are actually aluminum or another metal base coated with a ceramic-derived non-stick layer.

This ceramic coating provides the non-stick benefits consumers seek while keeping costs manageable and improving heat conductivity through the metal core.

Sol-gel, silica-based coating explanation

The ceramic coating on most modern cookware uses sol-gel technology, a process that creates a silica-based (sand-derived) layer bonded to the metal surface.

This coating is applied as a liquid solution that hardens through a curing process, forming a glass-like surface.

The silica particles create a smooth, naturally slippery layer that allows food release without synthetic chemicals.

This technology represents a significant departure from traditional polymer-based non-stick coatings.

PFAS-free + non-stick claims

One of ceramic cookware’s strongest selling points is its PFAS-free formulation.

Unlike conventional non-stick pans that may contain per- and polyfluoroalkyl substances (PFAS), ceramic coatings achieve their slickness through inorganic mineral compounds.

When comparing ceramic with non-stick coatings, ceramic options avoid the “forever chemicals” associated with Teflon and similar surfaces.

However, the non-stick performance of ceramic typically doesn’t match that of traditional PTFE coatings and diminishes more quickly over time.

Heavy metal considerations (lead/cadmium in cheap imports)

The most concerning safety issue with ceramic cookware involves heavy metal contamination.

Inexpensive ceramic pieces, particularly imports lacking proper certification, have tested positive for lead and cadmium in their glazes or coatings.

These toxic metals can leach into food, especially when cooking acidic ingredients.

It’s crucial to check if your cookware is heavy-metal safe by purchasing from reputable brands that provide third-party testing certificates and comply with FDA standards for food-contact surfaces.

What Is Stainless Steel Cookware?

Stainless steel has long been the professional chef’s choice, valued for its durability and versatility.

Understanding its composition helps explain why it performs differently than ceramic alternatives in the which is better, ceramic or stainless steel question.

304 vs 316 stainless steel (nickel content)

Stainless steel cookware primarily uses two grades: 304 (18/8) and 316 (18/10).

The numbers indicate chromium and nickel percentages—304 contains 18% chromium and 8% nickel, while 316 has 18% chromium and 10% nickel.

The 316 grade also includes molybdenum, making it more resistant to corrosion and pitting.

Both grades are food-safe, though individuals with severe nickel sensitivities should be aware that small amounts may leach when cooking highly acidic foods for extended periods.

Multi-ply construction (3-ply, 5-ply)

Quality stainless steel cookware features multi-ply construction, bonding layers of different metals.

A 3-ply pan typically sandwiches an aluminum or copper core between two stainless steel layers, combining stainless steel’s durability with aluminum’s superior heat conductivity.

Five-ply construction adds additional layers for even better heat distribution and control.

This layered approach addresses stainless steel’s naturally poor heat conductivity while maintaining its non-reactive cooking surface.

Non-reactive metal surface

Stainless steel’s chromium content creates a passive oxide layer that makes it non-reactive with acidic or alkaline foods.

Unlike bare aluminum or cast iron, stainless steel won’t impart metallic flavors to tomato sauces, wine reductions, or citrus-based dishes.

This chemical stability makes it ideal for diverse cooking applications without concerns about unwanted reactions that could alter taste or potentially increase metal exposure.

Why professional chefs use stainless steel

Professional kitchens overwhelmingly favor stainless steel for several practical reasons.

It withstands high heat without damage, allows for proper browning and fond development (those flavorful browned bits), survives the rigors of commercial dishwashers, and lasts decades under intense daily use.

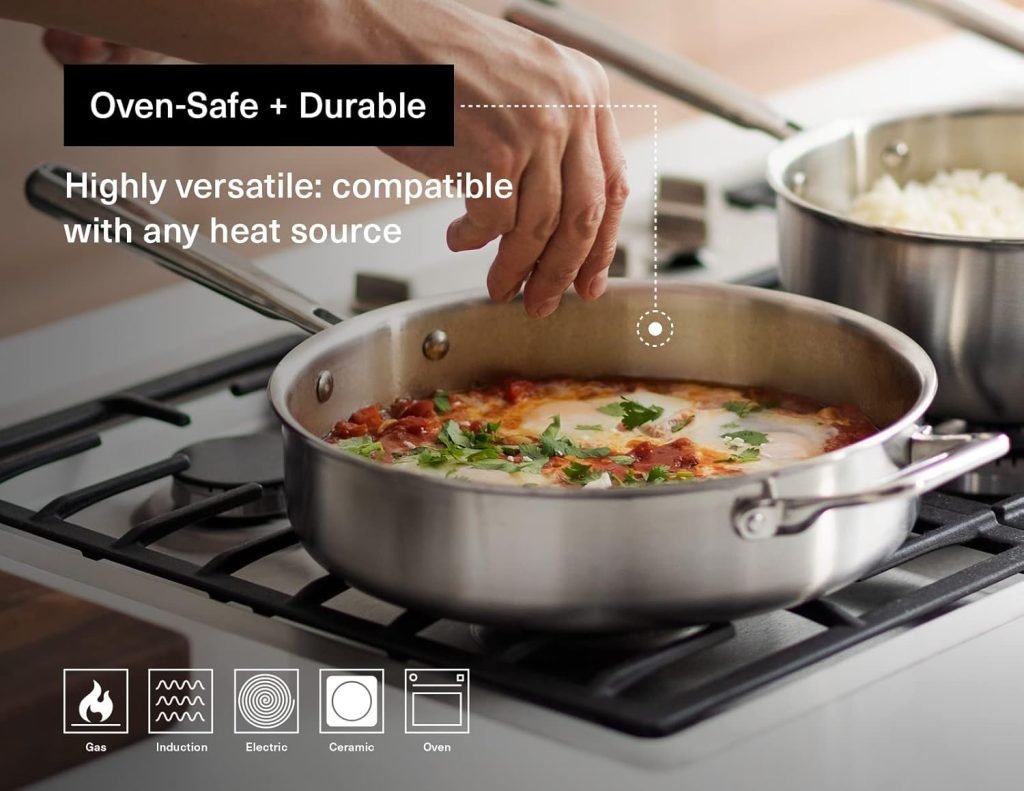

When comparing stainless steel vs ceramic heat performance, stainless steel’s ability to tolerate broiler-level temperatures and transition from stovetop to oven makes it indispensable for serious cooking.

Key Differences Between Ceramic and Stainless Steel

Understanding the fundamental distinctions between these materials reveals why they perform so differently in real-world cooking scenarios.

The ceramic cookware vs stainless steel comparison centers on several key factors.

Coating vs uncoated metal

The most fundamental difference lies in surface composition.

Ceramic cookware relies on an applied coating that sits atop a metal base, creating a barrier between food and the underlying material.

This coating delivers non-stick properties but represents a vulnerable layer that can degrade.

Stainless steel, conversely, features an uncoated metal surface what you see is what contacts your food.

There’s no coating to wear away, chip, or break down over time, though this also means it lacks inherent non-stick properties.

Weight differences

Ceramic-coated cookware typically feels lighter than comparable stainless steel pieces.

The aluminum base commonly used beneath ceramic coatings weighs less than stainless steel, making ceramic pans easier to maneuver for some cooks.

However, quality stainless steel’s substantial weight provides stability on the stovetop and indicates solid multi-ply construction.

The weight difference becomes noticeable when handling larger skillets or saucepans during cooking and cleaning.

Heat response & control

Ceramic-coated aluminum heats quickly due to aluminum’s excellent thermal conductivity, making it responsive to temperature changes.

However, ceramic coatings can develop hot spots if the underlying metal is thin.

Stainless steel, especially in multi-ply construction, heats more slowly but offers superior heat retention and more even temperature distribution once warmed.

Professional cooks value this predictability for precise cooking techniques requiring consistent heat.

Cooking versatility

Stainless steel handles virtually any cooking method, searing, deglazing, oven-finishing, broiling, and even metal utensil use. Its durability permits high-heat techniques that would damage ceramic coatings.

Ceramic cookware excels at low-to-medium heat cooking, where its non-stick properties shine, but struggles with high-heat applications.

The coating can break down above 500°F, and rapid temperature changes may cause damage. This versatility gap significantly impacts which cookware suits your cooking style.

Safety Comparison — Chemicals, Leaching & Coating Risks

Health considerations drive many consumers toward ceramic options, but the ceramic vs stainless steel safety picture is more complex than marketing suggests.

Ceramic – PFAS-free but may wear or chip

Ceramic coatings legitimately avoid PFAS chemicals, offering a genuine advantage over traditional non-stick surfaces. However, this doesn’t guarantee complete safety.

As ceramic coatings age, they may chip or flake, potentially introducing coating particles into food.

While generally considered inert, ingesting coating fragments isn’t ideal.

More concerning, if the coating deteriorates enough to expose the underlying aluminum, direct contact between acidic foods and aluminum becomes possible.

When you learn the safety profile of ceramic coatings, understanding both the PFAS-free benefit and degradation risks provides a complete picture.

Stainless steel – nickel leaching in acidic foods

The primary safety concern with stainless steel involves nickel leaching, particularly relevant for those with nickel allergies or sensitivities.

Research shows that stainless steel does leach nickel in measurable amounts when cooking highly acidic foods like tomato sauce for extended periods, especially in new cookware, before the passive chromium oxide layer fully develops.

This nickel leaching depends on factors such as the grade of stainless steel, cooking time, and cookware usage history.

For example, the study using tomato sauce, nickel leaching was as high as 88 micrograms per serving even after the tenth cooking cycle, with new cookware showing the largest increases.

However, the amounts are typically minimal and pose risk primarily to individuals with diagnosed nickel sensitivity. For most users, stainless steel presents minimal health concerns.

Lead & cadmium risks (ceramic glaze vs pure ceramic)

Heavy metal contamination represents the most serious safety issue in ceramic cookware.

Low-quality ceramic glazes have tested positive for lead and cadmium—neurotoxic heavy metals with no safe exposure level.

These metals may leach into food, especially when cooking acidic dishes. Pure ceramic from reputable manufacturers undergoes testing to ensure safety, but cheap imports often skip these safeguards.

Always verify third-party testing certificates and FDA compliance when purchasing ceramic cookware to avoid this hidden danger.

Prop 65 warnings, FDA standards, and safety testing

California’s Proposition 65 requires warnings for products containing certain chemicals, and some cookware carries these labels.

FDA standards regulate materials that contact food, setting limits for metal leaching. Reputable stainless steel manufacturers easily meet these standards.

For ceramic cookware, look for certification from independent labs confirming lead-free, cadmium-free status and compliance with FDA food-contact regulations.

These certifications assure that marketing claims match actual safety performance.

Cooking Performance Comparison

Beyond safety, how these materials perform during actual cooking significantly impacts user satisfaction in the stainless steel vs ceramic nonstick choice.

Non-stick performance (ceramic wins)

Ceramic cookware delivers superior non-stick performance, especially when new.

Eggs slide effortlessly, pancakes release cleanly, and delicate fish fillets lift without tearing.

This ease of use makes ceramic appealing for everyday cooking tasks. However, this advantage proves temporary ceramic’s non-stick properties diminish noticeably after several months of regular use.

Stainless steel offers no inherent non-stick qualities, requiring proper preheating, adequate fat, and technique to prevent sticking.

Experienced cooks master these skills, but beginners often struggle initially.

Searing & browning (stainless steel wins)

For developing rich flavors through Maillard reactions, the browning that creates complex tastes in seared steaks, caramelized onions, and pan-roasted chicken, stainless steel excels.

Its uncoated metal surface tolerates the high heat necessary for proper browning without degrading.

The fond that develops on the stainless steel surface becomes the foundation for pan sauces through deglazing.

Ceramic coatings can’t handle the same heat intensity and don’t develop fond effectively, limiting flavor development in certain dishes.

Heat retention & responsiveness

Ceramic-coated aluminum responds quickly to temperature adjustments, heating and cooling rapidly.

This responsiveness helps prevent overcooking but may lead to temperature fluctuations.

Quality multi-ply stainless steel retains heat more effectively, maintaining steady temperatures even when adding ingredients.

This stability proves valuable for techniques requiring consistent heat.

However, stainless steel’s slower response means adjusting heat takes longer to affect cooking temperature—a trade-off between stability and adaptability.

Which one needs more oil?

Ceramic cookware requires minimal oil or butter when new, making it attractive for health-conscious cooking.

As the coating ages, more fat becomes necessary to prevent sticking. Stainless steel consistently demands adequate fat for most cooking tasks—not excessive amounts, but enough to create a barrier between food and metal.

Proper preheating and the “water droplet test” (when water beads and rolls) signal readiness, allowing cooking with moderate oil use. Neither material enables truly oil-free cooking long-term.

Durability & Lifespan

Does ceramic cookware last long question frequently arises when comparing long-term value against stainless steel’s renowned longevity.

Stainless steel – decades of usage, scratch-resistant

Quality stainless steel cookware routinely lasts 20-30 years or more with proper care.

Its solid metal construction resists scratching from metal utensils, though abrasive scrubbing may leave minor marks that don’t affect performance.

The uncoated surface means there’s nothing to wear away—what starts as a scratch-resistant, durable pan remains that way indefinitely.

Many families pass down stainless steel cookware across generations, a testament to its extraordinary lifespan.

This durability makes the higher upfront cost more palatable when calculated per year of use.

Ceramic – coating wears in 1–3 years

Ceramic coatings typically maintain optimal non-stick performance for 1-3 years with careful use.

Daily cooking accelerates wear, as does high heat, metal utensils, and dishwasher cycles.

The coating gradually loses its slickness, requiring more oil and making food stick increasingly problematic.

While the pan remains usable, it no longer delivers the non-stick experience that justified the purchase.

Some users replace ceramic cookware every 2-3 years, making the long-term cost comparable to or exceeding stainless steel despite lower initial prices.

Chip vs scratch resistance

Ceramic coatings are prone to chipping, especially around edges and rivets.

Thermal shock from rapid temperature changes, accidental impacts, and metal utensil use all risk damaging the coating.

Once compromised, chips may expand with continued use. Stainless steel scratches rather than chips—these surface marks don’t progress or compromise functionality.

Scratches are largely cosmetic, whereas ceramic chips expose the underlying metal and create surfaces where bacteria might harbor and food can stick.

Long-term cost efficiency

Initial price comparisons favor ceramic cookware, but lifespan dramatically affects true cost efficiency.

A $100 ceramic pan replaced every 2-3 years costs $300-500 over 10 years.

A $200 stainless steel pan lasting 20+ years costs $200 over that period, half the expense with superior performance throughout.

Factor in frustration from degraded non-stick performance, and stainless steel’s value proposition strengthens considerably.

Budget-conscious consumers should calculate the cost per year of satisfactory use rather than the purchase price alone.

Ease of Use & Maintenance

Daily care requirements influence long-term satisfaction with either material. Understanding maintenance needs helps set realistic expectations.

Cleaning ceramic (gentle, non-abrasive)

Ceramic cookware demands gentle cleaning to preserve coating integrity.

Use soft sponges or cloths with mild dish soap—never abrasive scrubbers, steel wool, or harsh cleansers that accelerate coating breakdown.

Most food residue releases easily when soaked in warm, soapy water.

Avoid temperature extremes like plunging hot pans into cold water, which may crack the coating.

While initially easy to clean thanks to non-stick properties, maintenance becomes more challenging as the coating ages and food begins sticking more readily.

Cleaning stainless steel (deglazing + powder cleaners)

Stainless steel tolerates aggressive cleaning without damage.

Stuck-on food responds to deglazing, adding liquid to a hot pan to loosen fond, or soaking followed by scrubbing with powder cleansers like Bar Keeper’s Friend.

The metal surface withstands steel wool and abrasive sponges when necessary.

While stainless steel requires more effort to clean than fresh ceramic, its durability means you needn’t worry about damaging it.

Learning proper cleaning techniques, including using baking soda pastes for stubborn stains, makes maintenance straightforward.

Dishwasher safety

Most stainless steel cookware is genuinely dishwasher-safe, though hand washing extends its aesthetic appeal by preventing water spots and mineral deposits.

The harsh detergents and high heat of dishwashers don’t damage the metal.

Ceramic cookware manufacturers often claim dishwasher safety, but repeated dishwasher cycles accelerate coating degradation.

Hand washing with gentle methods preserves ceramic coatings longer.

If convenience matters most, stainless steel better accommodates dishwasher use without compromising performance or longevity.

Handling stains & discoloration

Stainless steel develops rainbow-hued heat stains and white calcium deposits from hard water.

These discolorations are harmless and removable with vinegar or specialized cleaners. The metal itself doesn’t stain permanently.

Ceramic coatings may develop permanent discoloration from high heat or certain foods, creating brown or darkened areas that won’t clean away.

While cosmetic, these stains affect appearance. Neither material’s discoloration issues impact food safety, but stainless steel’s stains prove easier to remove when desired.

Environmental & Sustainability Impact

Eco-conscious consumers increasingly consider environmental factors when choosing between eco-friendly ceramic vs stainless steel options.

Ceramic – eco-marketed but shorter lifespan

Ceramic cookware benefits from eco-friendly marketing emphasizing PFAS-free coatings and “natural” materials.

These claims hold merit regarding chemical content. However, the short 1-3 year lifespan creates significant waste.

Frequently replacing cookware generates manufacturing emissions for each new piece, consumes raw materials repeatedly, and sends old pans to landfills, where ceramic coatings and aluminum bases persist.

The environmental cost of repeated production and disposal undermines initial “green” advantages, making ceramics’ overall sustainability profile less impressive than marketing suggests.

Stainless steel – fully recyclable, long-lasting

Stainless steel’s exceptional durability represents its greatest environmental strength.

A single piece lasting 20-30 years eliminates the manufacturing impact and waste generation of multiple replacements.

When stainless steel eventually reaches end-of-life, it’s 100% recyclable—the metal retains value and can be endlessly reprocessed without quality degradation.

Recycled stainless steel requires less energy than virgin production.

This combination of longevity and recyclability makes stainless steel one of cookware’s most sustainable choices, despite higher initial resource requirements.

Manufacturing emissions differences

Ceramic coating production involves chemical processes and high-temperature curing that generate emissions.

The aluminum bases frequently used beneath ceramic coatings require energy-intensive production.

Stainless steel manufacturing also demands significant energy, particularly for mining, refining, and forming the alloys.

However, stainless steel’s longer lifespan means these manufacturing emissions are amortized over decades rather than years.

Per year of use, stainless steel’s manufacturing footprint becomes considerably smaller than repeatedly producing ceramic cookware.

Waste generation comparison

Short-lived ceramic cookware creates more frequent waste streams.

When coatings fail, entire pans become refuse despite functional metal bases underneath—recycling programs rarely accept coated cookware due to material separation challenges.

Stainless steel generates minimal waste over its lifetime, and end-of-life recycling captures material value.

For those prioritizing waste reduction, stainless steel’s durability advantage translates directly into environmental benefit. The most sustainable cookware is that which never needs replacing.

Which Cookware Should You Choose? (Use-Case Recommendations)

Selecting between ceramic and stainless steel depends on your priorities, cooking style, and willingness to develop technique. Consider these specific scenarios.

Best for searing – Stainless Steel

For achieving restaurant-quality sears on steaks, chops, and fish, stainless steel is unmatched.

Its ability to withstand high heat without degradation, develop flavorful fond, and tolerate metal utensils makes it ideal for searing techniques.

The uncoated surface promotes proper browning through direct contact with hot metal.

When you compare enamel vs non-stick coating for high-heat cooking, uncoated stainless steel consistently outperforms coated options.

Ceramic coatings simply cannot handle the temperatures necessary for optimal searing results without risking damage.

Best for low-oil cooking – Ceramic

New ceramic cookware enables cooking with minimal added fats, making it appealing for health-focused diets.

Eggs, pancakes, and delicate proteins cook successfully with light oil application or even cooking spray.

This advantage makes ceramic attractive for weight management and heart-healthy cooking styles.

However, recognize this benefit diminishes as coatings age—plan to use progressively more oil or replace the cookware every few years to maintain low-fat cooking capabilities.

Best for longevity – Stainless Steel

Nothing rivals stainless steel’s lifespan. Quality pieces last generations with basic care, making them true investment pieces.

The absence of coatings eliminates wear-related failure modes—there’s nothing to degrade except aesthetics.

For consumers tired of replacing cookware or wanting pieces that last decades, stainless steel is the clear choice.

The learning curve for preventing sticking proves worthwhile, given the extended service life and consistent performance year after year.

Best for toxin-free – High-quality stainless steel or pure ceramic (not coated ceramic)

For genuinely toxin-conscious cooking, high-quality stainless steel from reputable manufacturers offers the safest option for most people.

It avoids PFAS, and minimal nickel leaching poses risk only to those with specific sensitivities.

If choosing ceramic, invest in pure ceramic from certified manufacturers with third-party testing confirming no lead, cadmium, or other heavy metals.

Avoid inexpensive ceramic-coated options lacking proper certification; the heavy metal risk outweighs any potential benefits.

Stainless steel’s transparency and established safety record make it a more reliable choice than non-toxic alternatives.

FAQs — Ceramic vs Stainless Steel

Which heats better?

Ceramic-coated cookware heats faster due to aluminum cores, but quality multi-ply stainless steel distributes heat more evenly.

Ceramic’s quick response helps with temperature-sensitive cooking, while stainless steel’s even heating prevents hot spots and provides better control for precise techniques.

Is ceramic safer than steel?

Not necessarily. While ceramic avoids PFAS chemicals, cheap ceramic pieces may contain lead or cadmium.

Quality stainless steel poses minimal risk for most people, with only those highly sensitive to nickel needing caution.

Both can be safe when purchased from reputable manufacturers with proper certifications.

Is stainless steel good for non-stick cooking?

Stainless steel isn’t naturally non-stick, but proper technique—preheating, using adequate fat, and timing food release correctly—achieves satisfactory results.

It requires more skill than ceramic but delivers consistent performance indefinitely without coating degradation affecting non-stick qualities over time.

Final Verdict — Ceramic for Convenience, Stainless Steel for Safety & Longevity

The ceramic vs stainless steel cookware decision ultimately hinges on your priorities.

Ceramic delivers beginner-friendly convenience with excellent initial non-stick performance and minimal oil requirements, making everyday cooking effortless.

However, these benefits prove temporary as coatings inevitably degrade within a few years.

Stainless steel demands more technique but rewards users with superior durability, consistent performance across decades, and fewer chemical concerns.

It handles high-heat cooking that develops complex flavors, transitions seamlessly from stovetop to oven, and withstands the rigors of daily use without meaningful deterioration.

For most everyday cooks who prioritize long-term value, safety, and versatility, stainless steel represents the better investment.

Its learning curve becomes manageable with practice, while its advantages compound over the years of reliable service.

Ceramic suits those wanting immediate non-stick convenience and are willing to accept frequent replacement costs.

Consider purchasing one quality stainless steel skillet for high-heat tasks while using ceramic for gentler, everyday cooking.

Combining both materials provides the benefits of each while minimizing their respective limitations.