Standing in the cookware aisle, staring at gleaming pans promising effortless cooking, you’re faced with a decision that affects more than just tonight’s dinner.

The ceramic vs non-stick cookware comparison has intensified as aspiring chefs or food lovers become increasingly aware of what’s actually touching their food.

One promises chemical-free peace of mind, the other delivers that legendary slippery surface where eggs glide like magic.

But which one truly belongs in your kitchen? With conflicting claims about safety, durability, and performance swirling around both options, you need clear answers, not manufacturer hype.

This guide cuts through the confusion, examining the real differences between ceramic and traditional non-stick cookware, so you can make an informed choice that protects both your health and your wallet.

What Is Ceramic Cookware?

Ceramic cookware has surged in popularity as consumers seek alternatives to traditional chemical coatings.

Understanding what ceramic actually means and what it doesn’t is essential before investing in these trendy pans.

Pure ceramic vs ceramic-coated aluminum

True ceramic cookware comes in two distinct forms. Pure ceramic pieces are made entirely from clay hardened at high temperatures, creating naturally non-stick surfaces without any metal base.

These are relatively rare and expensive. Most “ceramic cookware” on the market is actually aluminum or stainless steel with a ceramic-style coating applied to the cooking surface.

This ceramic coating mimics the properties of pure ceramic but allows for lighter, more affordable pans.

If you want to learn about ceramic toxicity & composition, understanding this distinction is critical; the base metal matters as much as the coating.

Sol-gel silica-based coating process

The ceramic coating on most modern pans isn’t traditional kiln-fired clay.

Instead, manufacturers use a sol-gel process that creates a silica-based coating derived from sand.

This liquid solution is sprayed onto the metal base and then cured at high temperatures, forming a hard, glass-like surface.

The result is a smooth, naturally slick finish that doesn’t rely on synthetic polymers.

This mineral-based technology represents a significant departure from chemical coatings, though the quality varies dramatically between manufacturers.

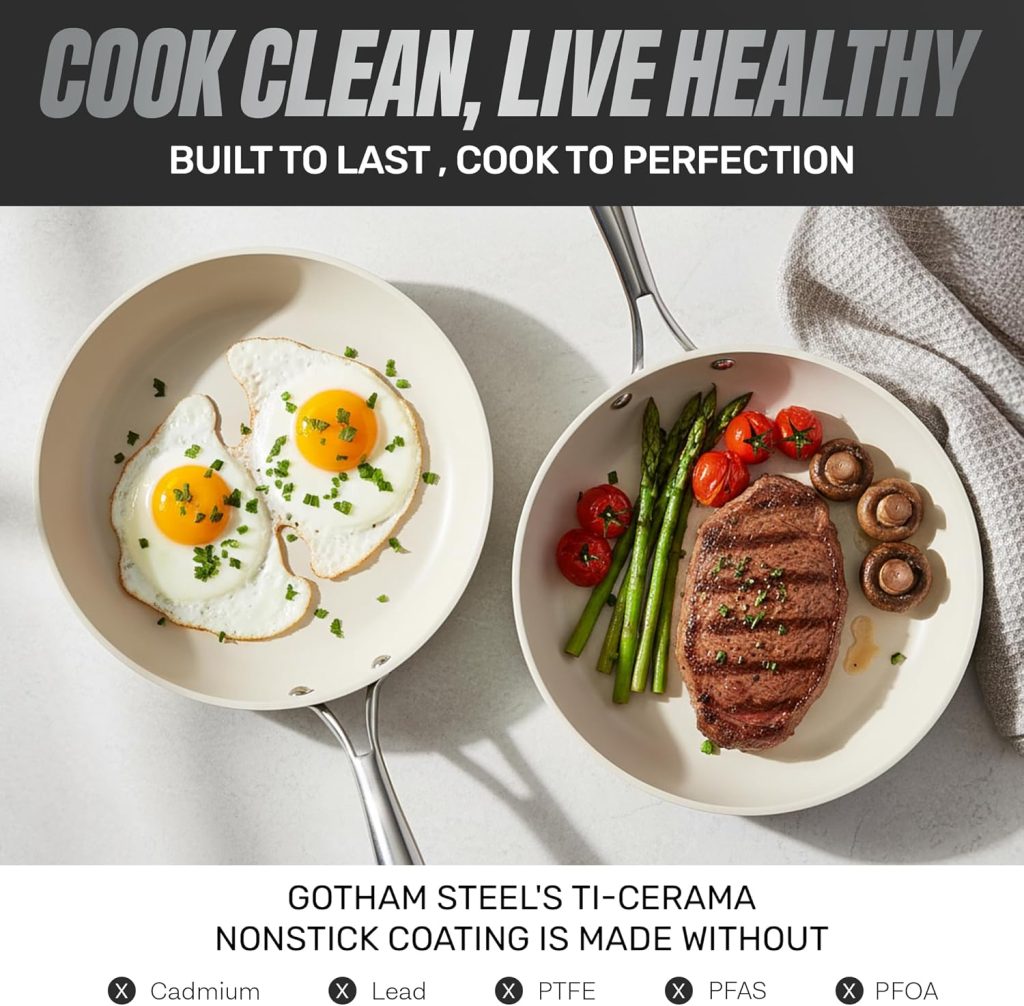

Why is ceramic marketed as PFAS-free?

Ceramic cookware’s primary selling point is its complete absence of PFAS chemicals—the “forever chemicals” associated with health concerns.

Unlike conventional non-stick surfaces that require fluoropolymers, ceramic coatings achieve their slickness through inorganic mineral compounds.

This PFAS-free status appeals to health-conscious consumers worried about chemical exposure.

However, “PFAS-free” doesn’t automatically mean “completely safe,” as we’ll explore in the next section.

Potential risks (cheap imports, heavy metals, chipping)

Not all ceramic cookware is created equal. Cheap imports, particularly from manufacturers with lax quality control, have tested positive for lead, cadmium, and other heavy metals in the coating or glaze.

The ceramic coating can also chip or flake with improper care, potentially exposing the aluminum base underneath.

Additionally, low-quality ceramic loses its non-stick properties quickly, sometimes within months.

Investing in reputable brands with third-party testing certifications is crucial for safety and longevity.

What Is Traditional Non-Stick Cookware?

Traditional non-stick cookware has dominated kitchens for decades, offering unmatched cooking convenience.

But understanding what makes these pans so slippery requires looking at the chemistry beneath the surface.

PTFE / Teflon polymer coating

Non-stick cookware relies on polytetrafluoroethylene (PTFE), commonly known by the brand name Teflon.

This synthetic fluoropolymer creates an incredibly smooth, low-friction surface that repels food, oil, and water.

PTFE’s unique molecular structure makes it one of the slipperiest substances on Earth.

When you see pans marketed as “non-stick,” they almost certainly feature PTFE unless specifically labelled otherwise.

To get a full guide on PTFE/PFAS risks, you need to understand how this coating interacts with heat and cooking conditions.

Aluminum base + polymer layering

Most non-stick pans feature an aluminum body chosen for its excellent heat conductivity and lightweight properties.

The PTFE coating is applied in multiple thin layers, sometimes with a primer layer to improve adhesion.

Higher-end non-stick cookware may include reinforced coatings with harder particles mixed into the PTFE for improved durability.

The aluminum base heats quickly and evenly, while the polymer coating provides the non-stick performance, a combination that explains traditional non-stick’s enduring popularity.

PFAS chemicals (PFOA, GenX)

PTFE itself is chemically stable, but its manufacturing historically involved PFOA (perfluorooctanoic acid), a PFAS compound linked to health problems.

While PFOA was phased out in 2013, it’s been replaced by similar chemicals like GenX.

These substances can persist in the environment and accumulate in human bodies.

Modern “PFOA-free” labels only address one specific chemical, not the entire class of PFAS compounds potentially used in production.

This semantic distinction matters when evaluating safety claims.

Why PTFE remains widely used

Despite concerns, PTFE cookware remains the best-selling non-stick option globally.

Its superior non-stick performance, affordability, and longer lifespan compared to ceramic make it hard to replace.

For many passionate cooks, the convenience of truly effortless egg cooking and minimal oil requirements outweighs potential concerns, especially when used properly at recommended temperatures.

The food industry also relies heavily on PTFE for commercial cooking, further cementing its position in the market.

Key Differences Between Ceramic and Non-Stick Coatings

When you compare ceramic to PTFE-based coatings, several fundamental differences emerge beyond just marketing claims.

These distinctions affect everything from daily cooking to long-term safety.

PFAS-free mineral coating vs synthetic polymer

The core difference lies in material composition.

Ceramic coatings are inorganic, mineral-based surfaces derived from silica, while PTFE is an organic synthetic polymer containing carbon-fluorine bonds.

Ceramic achieves its non-stick properties through an exceptionally smooth glass-like finish, whereas PTFE’s molecular structure inherently repels other substances.

This fundamental chemical difference means they respond differently to heat, wear, and potential health impacts.

Ceramic’s PFAS-free mineral coating appeals to those avoiding all synthetic chemicals, while PTFE’s engineered performance satisfies cooks prioritising function.

Chemical stability differences

PTFE is remarkably chemically stable at cooking temperatures below 500°F, resisting degradation from acids, oils, and cleaning agents.

Ceramic coatings are also stable but can be more reactive to thermal shock and abrasive cleaning.

However, PTFE breaks down at high temperatures (above 500°F), releasing potentially harmful fumes—a risk ceramic doesn’t share.

Conversely, ceramic coatings can lose their bonding to the metal base over time, leading to surface degradation that PTFE typically avoids when properly maintained.

Heat tolerance (ceramic higher)

Ceramic cookware typically tolerates temperatures up to 850°F before any coating degradation occurs, making it safer for high-heat searing, broiling, and oven use.

Traditional non-stick with PTFE should never exceed 500°F due to polymer decomposition risks.

This heat tolerance difference makes ceramic the clear winner for versatile cooking techniques requiring higher temperatures.

However, most stovetop cooking stays well below 500°F, meaning the heat advantage matters primarily for oven use and searing applications.

Surface smoothness & non-stick ability

PTFE delivers superior non-stick performance, especially when new. Food slides off effortlessly with minimal oil, making it unbeatable for delicate items like eggs and fish.

Ceramic starts with decent non-stick properties but never quite matches PTFE’s slickness, and ceramic’s performance degrades more quickly.

Within 6-12 months, many ceramic pans require more oil and develop sticky spots, while quality PTFE can maintain performance for years.

This performance gap explains why professional cooks often stick with traditional non-stick despite health concerns.

Safety Comparison — PFAS, Lead & Chemical Exposure

Safety concerns drive much of the ceramic vs Teflon comparison.

Understanding the actual risks, not just marketing fear, helps you make informed decisions about which is safer, ceramic or non-stick, for your household.

Ceramic – PFAS-free, may contain trace metals if poorly manufactured

Ceramic cookware eliminates PFAS exposure, a significant advantage for health-conscious consumers. However, “PFAS-free” doesn’t guarantee complete safety.

Lower-quality ceramic, especially imports without proper certification, can contain concerning levels of lead, cadmium, or other heavy metals in glazes or decorative elements.

These metals can leach into acidic foods over time. Reputable brands undergo third-party testing to ensure heavy metal compliance, but cheap ceramic pans pose genuine risks.

Always verify metal safety in cookware through certifications like FDA compliance or California Prop 65 testing.

Non-Stick – PFAS/PTFE fumes released at high heat

The primary concern with PTFE cookware involves overheating.

When non-stick pans exceed 500°F, the coating begins breaking down and releasing fumes containing PFAS compounds and other potentially toxic substances.

These fumes can cause flu-like symptoms in humans (“polymer fume fever”) and can be lethal to pet birds.

At normal cooking temperatures below 400°F, PTFE remains stable and doesn’t release measurable fumes.

The danger lies in empty preheating, forgotten pans, or high-heat searing—scenarios that responsible cooking practices can avoid.

Testing data (SGS, FDA, consumer advocacy reports)

Independent testing from organisations like SGS, Consumer Reports, and the FDA reveals nuanced safety profiles.

Modern PTFE cookware from reputable manufacturers shows minimal chemical migration into food when used properly.

However, scratched or degraded non-stick surfaces show increased PFAS release.

Ceramic cookware testing shows wide variability. Premium brands pass with flying colors, while budget options sometimes fail heavy metal tests.

The dangers of Teflon vs ceramic aren’t absolute; quality and proper use determine actual risk levels in both categories.

What modern “PFOA-free” labels really mean

“PFOA-free” labels on non-stick cookware are technically true but potentially misleading.

PFOA was banned in 2013, so virtually all cookware is now PFOA-free.

However, manufacturers replaced PFOA with chemically similar PFAS compounds like GenX, PFBS, or other fluorinated chemicals.

These alternatives haven’t been studied as extensively as PFOA, and early research suggests some may carry similar concerns.

“PFOA-free” doesn’t mean PFAS-free or chemical-free; it simply means one specific compound is absent.

For truly PFAS-free cookware, ceramic remains the only widely available non-stick option.

Non-Stick Performance Comparison

Beyond safety, performance matters. How well does each coating actually work for everyday cooking?

The ceramic vs PTFE non-stick performance gap is significant and changes over time.

Best low-oil cooking (non-stick wins)

For minimal-oil or oil-free cooking, traditional PTFE non-stick remains unbeatable.

You can literally cook eggs in a PTFE pan with zero added fat—they’ll slide around like they’re on ice.

Ceramic requires at least a light coating of oil for best results, even when new.

This difference matters for those following low-fat diets or simply preferring easier cleanup.

PTFE’s superior low-oil performance makes it the standard in commercial kitchens where speed and consistency trump all other concerns.

Natural non-stick performance (ceramic early-stage only)

Ceramic pans perform impressively when brand new, offering decent non-stick properties from their smooth, glass-like surface.

However, this performance is notoriously short-lived. Most ceramic coatings begin losing their slickness within 6-12 months, even with careful use.

Food starts sticking in spots, requiring more oil and scrubbing. By contrast, quality PTFE maintains consistent performance for 2-5 years with proper care.

The question of does ceramic cookware lasts with maintained non-stick properties has a disappointing answer, usually not beyond the first year.

High-heat cooking (ceramic wins)

Ceramic’s heat tolerance gives it a decisive edge for high-temperature techniques.

You can safely sear steaks, char vegetables, or finish dishes under the broiler without coating breakdown.

PTFE’s temperature ceiling of 500°F makes it unsuitable for these applications, limiting cooking versatility.

However, most everyday cooking—sautéing, scrambling eggs, making pancakes—occurs well below 400°F, where this advantage becomes theoretical rather than practical for many home cooks.

Which works better for eggs, fish, and pancakes

This comparison reveals the core trade-off. For ceramic vs nonstick for eggs, PTFE wins decisively—eggs release perfectly with zero sticking throughout the pan’s lifetime.

Fish fillets slide off cleanly without tearing delicate flesh. Pancakes flip effortlessly with beautiful, even browning.

Ceramic handles these tasks adequately when new, but struggles as the coating ages, often leaving stuck bits and requiring more oil.

If these delicate foods dominate your cooking, traditional non-sticks’ superior performance is hard to ignore, even considering safety concerns.

Durability & Lifespan

Understanding how long these pans actually last and what “longevity” really means is crucial for evaluating true value.

The non-stick vs ceramic durability comparison reveals surprising truths about replacement frequency.

Ceramic coating lifespan (1–3 years typical)

Most ceramic cookware delivers peak performance for just 6-12 months before noticeable degradation begins.

By 2-3 years, even well-maintained ceramic pans often lose most non-stick properties, developing sticky spots and requiring significantly more oil.

The coating doesn’t necessarily chip or flake—it simply stops working effectively.

This short functional lifespan disappoints many buyers who expected better durability from the premium prices that ceramic commands.

Only the highest-quality ceramic brands with reinforced coatings consistently exceed the 2-year mark.

Non-stick PTFE – longer durability, but chemical concerns

Quality PTFE cookware typically maintains effective non-stick performance for 3-5 years, sometimes longer, with exceptional care.

The coating proves more resilient to daily use, temperature cycling, and cleaning than ceramic.

However, scratches from metal utensils accelerate degradation and potentially increase chemical exposure.

This creates a paradox: PTFE lasts longer but raises ongoing safety questions throughout its extended lifespan.

For those comparing options, the choice often comes down to whether you’d rather replace ceramic frequently or use PTFE longer while accepting potential chemical exposure.

Scratch/chip resistance

Both coatings require careful handling, but PTFE generally shows better scratch resistance than ceramic.

Reinforced PTFE formulations with hard particles embedded in the coating can withstand more abuse.

Ceramic coatings, despite their glass-like hardness, tend to chip at edges and scratch from abrasive scrubbing more readily than quality non-stick.

Once scratched, a ceramic’s non-stick performance deteriorates rapidly in damaged areas.

Neither coating should ever contact metal utensils, but PTFE tolerates accidental scrapes better than ceramic.

Replacement frequency

Expect to replace ceramic cookware every 1-2 years if you cook frequently—a significant ongoing expense that catches budget-conscious buyers off guard.

Traditional non-stick might last 3-5 years, reducing replacement costs over time despite similar or lower initial prices.

When considering the PFAS-free ceramic cookware comparison, factor in total ownership costs, including replacements.

Frequent ceramic replacement also generates more waste, somewhat undermining its eco-friendly marketing.

The most economical approach might involve reserving ceramic for high-heat applications while using PTFE for everyday cooking, or switching to stainless steel or non-stick cookware for certain tasks.

Maintenance & Care Differences

Proper care dramatically affects performance and lifespan for both cookware types.

Following specific maintenance requirements can extend your investment and maintain safety.

Safe cleaning for ceramic

Ceramic requires gentle hand-washing with soft sponges and mild dish soap.

Avoid abrasive scrubbers, steel wool, or harsh cleansers that scratch the coating. Let pans cool completely before washing to prevent thermal shock that can crack the coating.

Stubborn residue can be removed by soaking in warm, soapy water or using a paste of baking soda and water.

Never use cooking sprays, as they build up a sticky residue that ruins ceramic’s non-stick properties faster than almost anything else.

Many manufacturers void warranties if cooking sprays are detected.

Non-stick: avoid metal utensils, high heat

PTFE cookware demands wood, silicone, or plastic utensils; only metal scratches compromise both performance and safety.

Never preheat empty non-stick pans, as they reach dangerous temperatures quickly without food to absorb heat.

Keep burners on low to medium settings; most foods cook perfectly below 400°F anyway.

Once PTFE shows visible scratching, peeling, or chipping, replace the pan immediately to minimise chemical exposure.

These restrictions feel limiting to some cooks, making the care requirements a significant practical consideration.

Dishwasher safety

Most manufacturers recommend hand-washing both ceramic and non-stick cookware, even if labelled “dishwasher safe.”

Dishwasher detergents are highly alkaline and abrasive, degrading coatings faster than hand-washing.

The intense heat and harsh chemicals strip the ceramic’s non-stick properties quickly.

For PTFE, dishwashers can cause coating delamination and premature failure.

If you value dishwasher convenience, consider our guide on carbon steel vs ceramic pan comparison or other options that tolerate machine washing better.

Ventilation needs for non-stick cooking

When using PTFE cookware, ensure adequate kitchen ventilation, especially at higher temperatures.

Turn on exhaust fans to remove any potential fumes before they accumulate.

Pet bird owners should avoid PTFE cookware entirely, as birds’ respiratory systems are extremely sensitive to polymer fumes—even normal cooking temperatures can be dangerous.

Ceramic requires no special ventilation considerations, offering peace of mind for households with pets or concerns about indoor air quality.

Environmental Impact

Both cookware types carry environmental consequences that extend beyond your kitchen.

Understanding these impacts provides a more complete picture for environmentally conscious consumers.

PFAS persistence & environmental harm (non-stick)

PFAS chemicals earned the nickname “forever chemicals” because they don’t break down in the environment—they persist indefinitely in soil and water.

Manufacturing PTFE cookware releases PFAS into ecosystems, where they accumulate in wildlife and eventually human bodies through food and water.

Even “PFOA-free” non-stick involves PFAS compounds with similar persistence.

This environmental burden continues long after your pan reaches the landfill.

Disposal of scratched or degraded PTFE cookware contributes to PFAS contamination in waste streams and potentially drinking water.

Ceramics’ eco-marketing vs short lifespan reality

Ceramic cookware markets itself as the eco-friendly alternative, highlighting natural materials and PFAS-free composition.

However, its 1-2 year lifespan creates a sustainability paradox.

Frequently replacing ceramic pans generates more waste, requires repeated manufacturing (an energy-intensive process), and increases shipping environmental costs.

The aluminum base in most ceramic cookware is recyclable, but the ceramic coating contaminates recycling streams.

True environmental impact calculation must include disposal frequency, not just material composition.

Waste generation & recyclability

Neither cookware type recycles well. The bonded coating-metal construction prevents easy separation, and most recycling facilities reject these pans.

PTFE creates toxic smoke when incinerated, making disposal particularly problematic. Ceramic-coated pans can’t be recycled due to coating contamination.

Both typically end up in landfills, where ceramics’ heavy metal risks and PTFE’s chemical persistence create different environmental concerns.

The most sustainable choice might be longer-lasting options like cast iron or stainless steel that last for decades.

Energy use in manufacturing

Manufacturing both ceramic and PTFE coatings requires significant energy.

Ceramic’s sol-gel process and high-temperature curing consume substantial electricity.

PTFE production involves complex chemical synthesis at elevated temperatures and pressures.

However, PTFE’s longer functional lifespan means fewer replacements and potentially lower lifetime manufacturing impact per cooking hour.

Ceramics’ need for frequent replacement may ultimately require more total manufacturing energy despite using “natural” materials.

Neither option clearly wins from a pure manufacturing energy perspective.

Which Should You Choose? (Use-Case Recommendations)

The right choice depends entirely on your priorities, cooking style, and personal values. Here’s how to decide based on specific use cases.

Best for low-oil frying – Non-stick

If minimal-oil cooking is your priority, whether for health reasons or convenience, traditional PTFE non-stick remains unmatched.

Nothing else allows truly fat-free cooking with consistently good results.

For daily egg breakfasts, delicate fish, or low-fat meal prep, PTFE’s superior performance justifies its use despite chemical concerns.

Just follow temperature guidelines strictly and ensure proper ventilation.

Best for toxin-free cooking – Ceramic

For households eliminating all PFAS exposure, ceramic is the only viable non-stick option.

If you’re pregnant, have young children, or simply want to minimise chemical exposure, ceramic’s PFAS-free composition provides peace of mind.

Accept the shorter lifespan and performance limitations as the cost of avoiding synthetic chemicals.

Choose certified brands to ensure the ceramic itself is free from heavy metals.

Best for high heat – Ceramic

For searing, broiling, or high-temperature oven use, ceramic’s superior heat tolerance makes it the clear choice.

You can safely push temperatures that would destroy PTFE and potentially release harmful fumes.

However, consider whether you actually cook at these high temperatures regularly; if most cooking stays below 400°F, this advantage becomes less relevant.

Best budget-friendly choice – Non-stick

Traditional PTFE offers better value over time due to a longer lifespan despite similar upfront costs.

Replacing ceramic every 1-2 years costs more than replacing quality non-stick every 3-5 years.

For budget-conscious cooks who cook daily and need reliable performance, traditional non-stick provides better cost-per-use economics.

The cheapest quality option, however, might be learning to cook with stainless steel or cast iron that lasts decades.

Best for long-term health – Ceramic or stainless steel

For minimising lifetime chemical exposure while maintaining some non-stick convenience, ceramic wins among coated options.

However, truly prioritising long-term health might mean skipping coated cookware entirely.

Stainless steel and cast iron eliminate all coating concerns while lasting indefinitely.

Many health-conscious cooks use ceramic for eggs and delicate foods while relying on uncoated cookware for everything else, a hybrid approach that balances convenience and safety.

FAQs — Ceramic vs Non-Stick Cookware

Which is truly safest?

Ceramic is safer regarding PFAS chemical exposure, containing zero fluoropolymers or forever chemicals.

However, low-quality ceramics can contain heavy metals.

High-quality ceramic from certified manufacturers offers the safest non-stick option.

PTFE is safe when used below 500°F, but it releases potentially harmful fumes at higher temperatures.

For absolute safety, uncoated stainless steel or cast iron remains the gold standard.

Is ceramic really non-toxic?

Quality ceramic from reputable manufacturers is non-toxic and free from PFAS, PTFE, lead, and cadmium.

However, “ceramic” is not automatically “non-toxic”—cheap imports sometimes contain concerning levels of heavy metals.

Always choose ceramic cookware with third-party safety certifications and test results.

The coating itself is inert and safe, but manufacturing quality determines actual toxicity levels.

Is non-stick totally safe if used on low heat?

When used below 400°F, PTFE non-stick is generally considered safe and doesn’t release measurable fumes or chemicals.

The coating remains stable at normal cooking temperatures.

However, scratched or damaged PTFE may release small particles into food, and proper temperature control requires vigilance.

For those uncomfortable with any PFAS exposure or unable to strictly monitor cooking temperatures, ceramic offers greater peace of mind despite performance compromises.

Final Verdict — Ceramic Wins for Safety, Non-Stick Wins for Convenience

The ceramic vs non-stick cookware comparison has no universal winner; your ideal choice depends on what you value most.

Ceramic delivers PFAS-free peace of mind, higher heat tolerance, and appeals to health-conscious cooks willing to sacrifice some performance and accept a shorter lifespan.

Traditional non-stick offers superior cooking performance, better durability, and unmatched low-oil convenience, but carries chemical concerns requiring careful temperature management.

For most households, the safest long-term approach combines high-quality ceramic for high-heat cooking and eggs with stainless steel or cast iron for everyday use.

If choosing between only these two options, ceramic edges are ahead for health-focused households, while traditional non-stick suits performance-oriented cooks who follow safety guidelines strictly.

The cookware industry continues evolving, with newer technologies promising both safety and performance.

Until then, understanding these trade-offs empowers you to choose cookware aligned with your health priorities, cooking style, and budget, not just commercial claims.