You’re standing in your kitchen, about to flip an omelette in your trusty non-stick pan, when a troubling thought crosses your mind: Is non-stick cookware safe for my family?

You’ve heard whispers about toxic chemicals, “forever chemicals,” and health risks linked to those convenient, easy-to-clean surfaces.

The pan that once felt like a kitchen essential now seems like a potential threat.

If you’ve been questioning whether your Teflon-coated skillet is secretly poisoning your breakfast, you’re not alone.

Millions of home cooks are grappling with the same concerns, caught between convenience and safety.

The truth about non-stick cookware isn’t as black-and-white as fear-driven headlines suggest, but it’s not entirely worry-free either.

This comprehensive guide cuts through the confusion with evidence-based facts about Teflon cookware safety, PFAS chemicals, overheating risks, and practical steps to protect your health without sacrificing your cooking experience.

What Is Non-Stick Cookware?

Non-stick cookware refers to pots and pans coated with specialised materials engineered to prevent food from adhering to the cooking surface.

This innovation transformed home cooking by eliminating the need for excessive oils or butter while making cleanup remarkably effortless.

The technology works by creating an ultra-smooth, low-friction surface at the molecular level, allowing eggs, fish, and delicate foods to slide off without sticking or tearing.

Types of Non-Stick Coatings

The non-stick cookware market offers several coating technologies, each with distinct characteristics:

- PTFE (Polytetrafluoroethylene/Teflon): The original and most common non-stick coating, known for exceptional food release and durability when properly maintained.

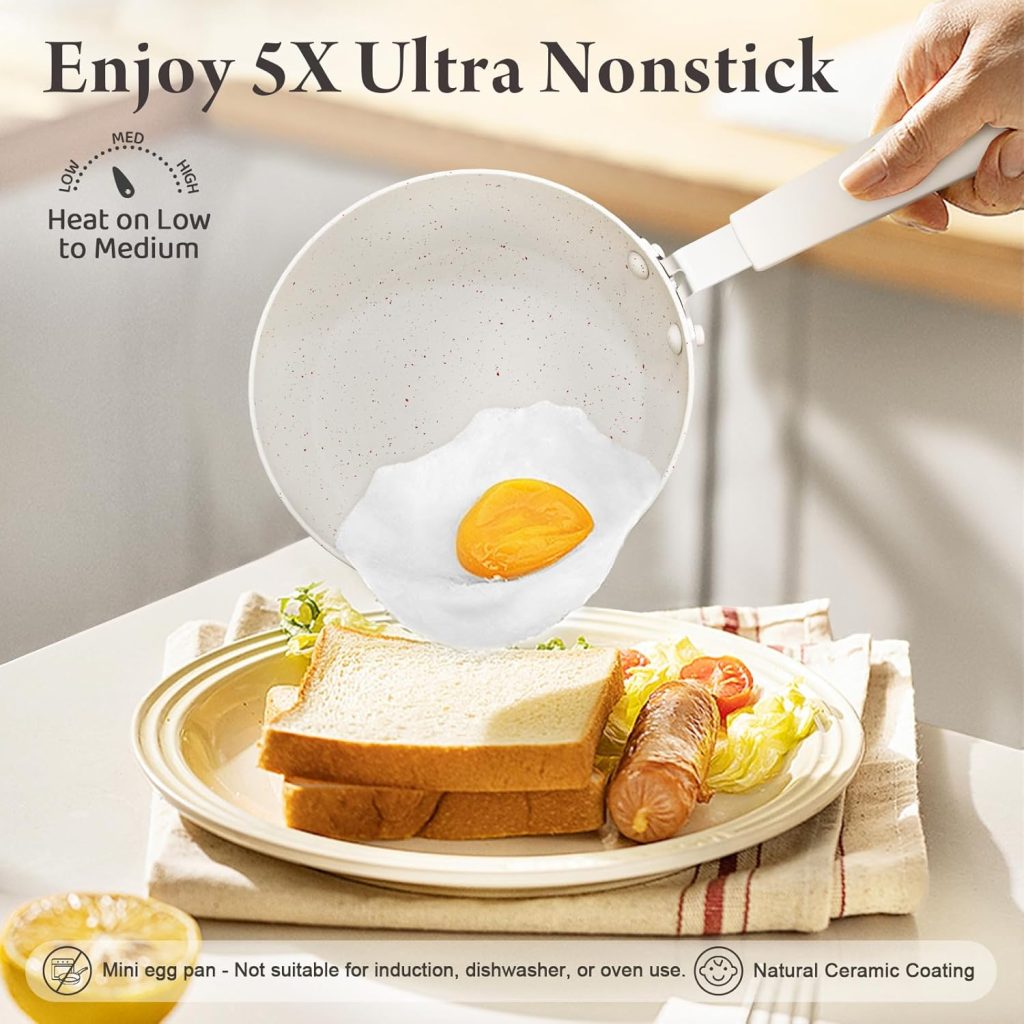

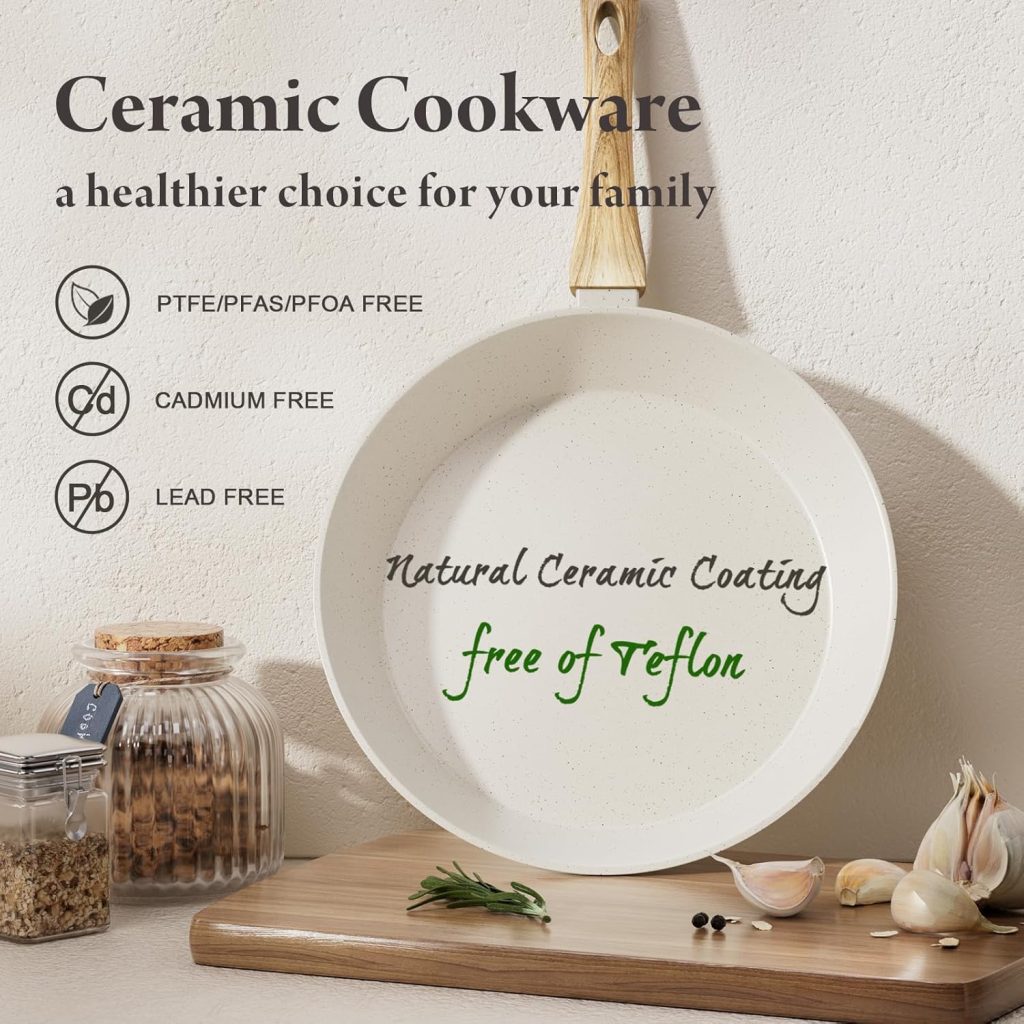

- Ceramic non-stick: Made from inorganic minerals and silicon, marketed as a natural alternative without PTFE or PFAS chemicals.

- Silicone-based coatings: Hybrid formulations combining silicone polymers with other materials for enhanced scratch resistance.

- Diamond-reinforced coatings: PTFE blended with diamond particles for improved hardness and longevity

Each coating type delivers varying levels of performance, durability, and safety profiles that matter when selecting cookware for your kitchen.

How Teflon Revolutionised Cookware Manufacturing

When DuPont scientist Roy Plunkett accidentally discovered PTFE in 1938, he unknowingly created a material that would revolutionise cooking.

By the 1960s, Teflon-coated pans became household staples, offering unprecedented convenience that fundamentally changed cooking habits worldwide.

The polymer’s remarkable properties, extreme slipperiness, heat resistance, and chemical inertness made it ideal for cookware applications.

However, the manufacturing process historically involved PFOA (perfluorooctanoic acid), a concerning chemical that would later trigger widespread safety investigations.

Understanding this history helps contextualise current safety standards and why modern PFOA-free cookware has become a critical consideration for health-conscious consumers.

For a broader perspective on materials, explore safe cookware materials to understand your full range of options.

Is Non-Stick Cookware Safe?

Yes, with conditions. Modern non-stick cookware manufactured after 2013 is safe when used correctly, keeping temperatures below 400°F, avoiding metal utensils, replacing damaged pans promptly, and ensuring proper ventilation.

PFOA has been phased out industry-wide, eliminating the most concerning manufacturing chemical.

However, PTFE coatings still contain PFAS compounds that persist in the environment, and overheating above 500°F releases toxic fumes.

For most healthy adults using non-stick cookware properly, immediate health risks are minimal.

That said, vulnerable populations (babies, pregnant women, those with compromised immune systems) and anyone unable to consistently maintain safe usage practices should consider PFAS-free alternatives like ceramic, stainless steel, or cast iron for complete peace of mind.

How Non-Stick Coatings Work

The Science of PTFE — Low Friction Polymer Surface

PTFE creates its legendary non-stick properties through an extraordinary molecular structure.

The polymer consists of carbon atoms surrounded by fluorine atoms, forming one of the strongest chemical bonds in nature.

This fluorine shield creates an incredibly low surface energy, meaning other molecules struggle to establish contact with the surface.

The coefficient of friction for PTFE ranks among the lowest of any solid material, which translates to that signature slippery feel.

When food contacts a PTFE surface, molecular adhesion forces remain too weak to create lasting bonds, allowing proteins and starches to release cleanly without tearing or sticking.

Why Nothing Sticks — Molecular-Level Explanation

At the microscopic level, food sticking involves complex interactions between surface texture, chemical bonding, and heat transfer.

Traditional metal cookware has microscopic peaks and valleys where food particles lodge and form chemical bonds during cooking.

PTFE coating fills these irregularities, creating an atomically smooth surface.

Additionally, the fluorine atoms surrounding the carbon backbone repel both water and oil molecules—a property called amphiphobicity.

This dual repellency means that, whether you’re cooking watery vegetables or fatty meats, neither can form the molecular grip needed for adhesion.

The coating essentially creates an invisible barrier that keeps your cooking surface pristine.

What Happens When Coating Overheats or Wears Off

Understanding what happens when non-stick pans overheat is crucial for safe usage.

When PTFE reaches temperatures above 500°F (260°C), it begins to degrade and release gaseous byproducts.

These fumes include fluoropolymers that can cause flu-like symptoms in humans, a condition called polymer fume fever or “Teflon flu.”

Birds are particularly vulnerable, with fatalities possible from exposure. Once a non-stick coating chips, scratches, or peels, the protective layer becomes compromised.

Exposed areas lose their non-stick properties and may allow tiny coating particles to flake into food.

While ingesting small PTFE particles is generally considered non-toxic because the material passes through the digestive system unchanged, damaged pans introduce inconsistent heating and potential contamination risks that justify replacement.

What Chemicals Are in Non-Stick Coatings?

PTFE (Teflon) and Its Chemical Structure

Polytetrafluoroethylene (PTFE), commercially known as Teflon, consists of long carbon chains where each carbon atom bonds with two fluorine atoms.

This repetitive structure (CF₂-CF₂)n creates a stable, inert polymer resistant to chemical reactions, heat, and degradation under normal cooking conditions.

The carbon-fluorine bond represents one of the strongest in organic chemistry, which explains PTFE’s exceptional stability.

Importantly, PTFE itself is considered chemically inert and non-toxic when used within recommended temperature ranges.

The safety concerns surrounding Teflon historically stemmed not from PTFE itself, but from chemicals used during its manufacturing process, specifically PFOA, which was phased out industry-wide by 2013.

PFOA, PFAS, and GenX — “Forever Chemicals” Explained

PFAS (per- and polyfluoroalkyl substances) represent a family of thousands of synthetic chemicals characterised by strong carbon-fluorine bonds that resist natural breakdown.

PFOA (perfluorooctanoic acid) was historically used as a processing aid in PTFE manufacturing.

These substances earned the nickname “forever chemicals” because they persist in the environment and human bodies for years, accumulating in water supplies, soil, and wildlife.

Studies have linked PFOA exposure to various health concerns, including thyroid disease, high cholesterol, pregnancy complications, and certain cancers.

GenX chemicals emerged as PFOA replacements, but research suggests they may carry similar environmental persistence and health risks.

The critical distinction: PFOA was never intended to remain in finished cookware; it was supposed to burn off during manufacturing, though trace amounts sometimes remained.

Why Older Pans (Pre-2013) Are Riskier

Cookware manufactured before 2013 poses greater concern because PFOA was still widely used in PTFE production processes during that era.

While manufacturers claimed the chemical burned off at high temperatures during curing, independent testing sometimes detected residual PFOA in finished products.

Additionally, older manufacturing standards lacked today’s rigorous safety protocols.

If you’re using non-stick pans from before 2013, especially those showing wear, degradation, or coating damage, replacement with modern alternatives offers measurable risk reduction.

The safest non-stick pans incorporate improved manufacturing standards that eliminate PFOA from production processes.

Modern PFOA-Free Coatings — What They Really Mean

When manufacturers advertise “PFOA-free” cookware, they’re confirming that perfluorooctanoic acid wasn’t used during production.

However, this designation doesn’t automatically mean PFAS-free, as other fluorinated compounds might still be present.

Truly PFAS-free non-stick cookware eliminates all per- and polyfluoroalkyl substances, typically using ceramic, silicone, or other alternative coating technologies.

Understanding this distinction matters when evaluating product claims. Some PTFE cookware remains PFOA-free but still contains PFAS due to the fluorinated nature of the polymer itself.

For a detailed comparison of coating technologies, review ceramic vs Teflon to understand the fundamental differences in chemical composition and safety profiles.

Is Non-Stick Cookware Toxic? The Science Explained

What Happens When Non-Stick Pans Are Overheated (>500°F / 260°C)

Temperature control represents the single most critical factor in non-stick pan toxicity prevention.

When PTFE coatings exceed 500°F (260°C), thermal decomposition begins, breaking down the polymer’s molecular structure.

At approximately 660°F (349°C), decomposition accelerates dramatically, releasing various fluorinated compounds into the air.

Empty pans can reach these dangerous temperatures within 2-5 minutes on high heat—faster than most cooks realise.

The safest temperature for non-stick cookware stays below 400°F (204°C), which accommodates most cooking techniques except searing and high-heat stir-frying.

Preheating empty pans represents a particularly risky practice, as nothing absorbs or dissipates the heat, allowing temperatures to spike rapidly.

Always add cooking oil or food before heating, use low to medium settings, and never leave non-stick pans unattended on active burners.

Teflon Flu (Polymer Fume Fever) and Chemical Off-Gassing

Polymer fume fever occurs when humans inhale fumes from severely overheated PTFE, causing temporary flu-like symptoms including chills, headaches, chest tightness, and fever.

Symptoms typically appear several hours after exposure and resolve within 12-48 hours without lasting effects.

While unpleasant, this condition doesn’t appear to cause permanent damage in humans.

However, pet birds are extremely susceptible to PTFE fumes, with exposure often proving fatal even at lower temperatures.

The fumes damage avian respiratory systems quickly and severely. If you keep birds, non-stick cookware presents serious risks regardless of careful usage.

Beyond polymer fume fever, overheating can release other compounds, including hydrofluoric acid, carbonyl fluoride, and perfluoroisobutylene (PFIB)—substances with varying toxicity levels that justify proper ventilation and temperature management.

Animal Studies and Environmental Persistence of PFAS

Laboratory studies on PFAS exposure in animals have documented concerning effects across multiple organ systems.

Research shows PFOA accumulates in the liver, kidney, and blood tissues, with links to liver damage, immune system suppression, developmental problems in offspring, and tumor formation in some studies.

The environmental persistence is equally troubling.

PFAS chemicals don’t break down naturally, contaminating water supplies near manufacturing facilities and accumulating in fish, wildlife, and agricultural products.

Biomonitoring studies detect PFAS in the blood of nearly all Americans, with primary exposure routes including contaminated drinking water, food packaging, stain-resistant treatments, and consumer products.

While cookware represents just one exposure source, minimising avoidable contact with PFAS chemicals aligns with precautionary health principles, especially for vulnerable populations like pregnant women and young children.

What Makes “Safe Use” Possible — Temperature and Care Limits

Despite legitimate concerns about Teflon cookware safety, proper usage significantly reduces risks.

The key lies in maintaining temperatures well below the decomposition threshold and replacing cookware before coating integrity fails.

Modern PFOA-free, responsibly manufactured non-stick cookware used correctly on low-medium heat with appropriate utensils and ventilation presents minimal immediate health risks.

The polymer itself doesn’t migrate into food at cooking temperatures, and the primary danger emerges only from overheating or degraded coatings.

However, “safe use” remains temperature-dependent and requires consistent vigilance factors that lead many health-conscious consumers toward inherently safer alternatives.

The question isn’t whether non-stick can be used safely under ideal conditions, but whether those conditions realistically persist throughout the product’s lifespan in busy home kitchens.

Are Non-Stick Pans Safe When Scratched?

Once the non-stick coating becomes scratched, chipped, or visibly worn, the pan’s safety profile changes significantly.

While small scratches may not immediately compromise cooking performance, they create pathways for coating particles to flake into food during cooking.

Although ingesting small PTFE particles is generally considered low-risk because the material passes through the digestive tract unchanged, damaged coatings also expose the underlying metal surface.

This exposure causes uneven heating, increases sticking in affected areas, and may accelerate further coating degradation.

More concerning, scratches indicate the protective barrier has failed, potentially allowing any residual manufacturing chemicals or contaminants to leach.

Deep scratches or peeling sections definitely warrant replacement.

As a safety guideline, retire non-stick pans when you notice any coating damage, discoloration, or when food consistently sticks despite proper care, usually within 2-5 years, depending on usage frequency and care quality.

When to Throw Away Non-Stick Pans?

Knowing when to replace non-stick cookware protects both cooking quality and health.

Discard non-stick pans immediately if you observe visible peeling, flaking, or large scratched areas where bare metal shows through.

Discoloration, warping, or persistent staining that doesn’t clean off also signals coating breakdown.

If food suddenly sticks in areas that previously released easily, the non-stick properties have degraded beyond effective use.

Additionally, pans manufactured before 2013 should be replaced regardless of visible condition due to potential PFOA contamination risks.

For optimal safety, consider replacing even well-maintained non-stick cookware every 3-5 years, as microscopic coating wear occurs with normal use even when damage isn’t visible.

When disposing of old pans, check local recycling programs, as some facilities accept cookware while others require special handling due to coating materials.

Investing in higher-quality alternatives like ceramic vs non-stick cookware options often provides better longevity and eliminates replacement frequency concerns.

Does Scratched Teflon Cause Cancer?

The relationship between scratched Teflon and cancer isn’t straightforward.

Current research indicates that PTFE itself, the polymer that forms Teflon coating, is biologically inert and doesn’t cause cancer when ingested in small amounts from scratched pans.

The material passes through the digestive system unchanged without being absorbed.

However, the cancer concerns stem from PFOA, the processing chemical historically used in PTFE manufacturing.

PFOA exposure has been linked to increased risk of kidney and testicular cancers in epidemiological studies of communities with contaminated water supplies and workers with occupational exposure.

The critical distinction: scratched pans don’t suddenly release PFOA into food. Any PFOA present was introduced during manufacturing, not liberated by physical damage.

That said, scratched, degraded coatings may harbor bacteria, release small particles, and signal overall pan deterioration.

While scratched Teflon alone doesn’t appear to cause cancer based on available evidence, it justifies replacement as part of prudent kitchen safety practices.

For those seeking to eliminate all PFAS exposure concerns, exploring whether ceramic cookware is healthy provides insights into genuinely PFAS-free alternatives.

Is Non-Stick Cookware Safe for Babies?

Parents preparing food for babies and toddlers rightfully scrutinise every potential chemical exposure.

While modern PFOA-free non-stick cookware used correctly at low temperatures doesn’t pose acute risks, the precautionary principle suggests extra caution for developing children.

Infants and young children face disproportionate vulnerability to environmental toxins due to their smaller body size, rapid development, and higher metabolic rates.

Their blood-brain barriers remain more permeable, and detoxification systems function less efficiently than in adults.

Additionally, babies have longer remaining lifespans for bioaccumulative chemicals to exert effects.

Given these vulnerabilities, many paediatricians and child health advocates recommend avoiding PTFE cookware for baby food preparation entirely.

Stainless steel, cast iron, or ceramic options eliminate PFAS exposure concerns while providing excellent cooking performance.

If using non-stick for convenience, never overheat pans, ensure adequate ventilation, replace at the first sign of wear, and prioritise products specifically certified as lead and PFAS-free cookware through independent testing.

For comprehensive safety assurance, consider testing your cookware for lead and cadmium through certified services, especially when preparing food for vulnerable family members.

Are Non-Stick Pans Safe for the Dishwasher?

Most non-stick cookware manufacturers explicitly advise against dishwasher use, and this recommendation directly impacts cookware safety and longevity.

Dishwashers expose pans to harsh detergents, high heat, and aggressive water jets that accelerate coating degradation far faster than hand washing.

The alkaline detergents can chemically attack the non-stick surface, while tumbling against other items causes physical abrasion.

This combination weakens coating adhesion to the underlying metal, promoting premature peeling, chipping, and flaking—the very damage that signals time for replacement.

While a single dishwasher cycle won’t immediately ruin quality non-stick pans, repeated exposure significantly shortens their useful lifespan from years to months.

Even cookware marketed as “dishwasher-safe” suffers accelerated wear compared to hand-washed equivalents.

For maximum safety and longevity, always hand-wash non-stick cookware with soft sponges, mild dish soap, and warm water.

This gentle approach preserves coating integrity, prevents premature damage, and ensures the pan maintains its non-stick properties throughout its intended lifespan without introducing the risks associated with compromised surfaces.

Symptoms of Teflon Poisoning in Humans

Acute Teflon poisoning, medically termed polymer fume fever, occurs specifically from inhaling fumes released when PTFE overheats dramatically (typically above 500°F/260°C).

Symptoms develop within 4-8 hours of exposure and may include:

- Flu-like symptoms with chills and body aches

- Fever ranging from mild to moderate elevation

- Chest tightness and shortness of breath

- Persistent dry cough

- Headache and general malaise

- Throat irritation

These symptoms typically resolve within 12-48 hours without medical intervention, though severe exposures may warrant medical evaluation.

Importantly, this condition results from fume inhalation, not from eating food cooked in non-stick pans or consuming coating particles.

Chronic low-level PFAS exposure through various environmental sources presents different concerns, with symptoms less acute and more systemic thyroid dysfunction, elevated cholesterol, immune suppression, and developmental effects appearing in populations with documented long-term PFAS exposure.

However, attributing vague symptoms specifically to cookware use proves difficult, given multiple exposure routes.

If you experience polymer fume fever symptoms after cooking, immediately ventilate the area, discontinue use of the implicated cookware, and consult a healthcare provider if symptoms persist or worsen.

Prevention remains the best approach: never overheat non-stick pans, ensure proper kitchen ventilation, and replace damaged cookware promptly.

Regulation & Safety Standards for Non-Stick Cookware

PFOA Phase-Out (2013) and PFAS Regulations (EPA, EU)

In response to mounting health and environmental evidence, the EPA launched the PFOA Stewardship Program in 2006, working with major manufacturers, including DuPont, to eliminate PFOA from production by 2015.

Most cookware companies completed the transition by 2013, fundamentally changing the non-stick pan toxicity landscape.

The European Union implemented even stricter regulations, restricting PFOA concentrations in consumer products to 25 parts per billion as of 2020.

More recently, regulatory attention has expanded beyond PFOA to encompass the broader PFAS family.

The EPA has proposed and finalised designating certain PFAS chemicals, specifically perfluorooctanoic acid (PFOA) and perfluorooctanesulfonic acid (PFOS), as hazardous substances under the Superfund law (CERCLA), which requires reporting releases and enables cleanup and liability measures.

Meanwhile, the European Union is considering a comprehensive restriction across all uses of PFAS chemicals, aiming for a broader ban beyond individual chemical designations.

Several U.S. states, including Maine, California, and Washington, have enacted laws phasing out PFAS in consumer products, including cookware.

These evolving regulations reflect scientific understanding of PFAS persistence and health implications, though enforcement and compliance monitoring vary significantly by jurisdiction and remain ongoing challenges.

FDA and Prop 65 Compliance Labels

The FDA regulates cookware under food contact substance guidelines, requiring that materials used don’t transfer harmful levels of substances into food under intended use conditions.

However, FDA approval doesn’t guarantee absolute safety; it confirms that when used as directed, the product meets minimum standards.

California’s Proposition 65 requires warning labels on products containing chemicals known to cause cancer or reproductive harm above specified threshold levels.

You’ll sometimes see Prop 65 warnings on non-stick cookware, particularly regarding lead or cadmium in ceramic glazes or PFAS-related substances.

These warnings don’t necessarily indicate dangerous products; they reflect California’s uniquely stringent disclosure requirements.

Savvy consumers look beyond basic FDA compliance, seeking products that voluntarily exceed minimum standards through third-party certification and testing transparency that confirms the absence of concerning substances rather than simply meeting legal minimums.

Brand Transparency and Independent Testing (SGS, Intertek)

Given regulatory limitations and variable enforcement, independent third-party testing provides the most reliable safety assurance.

Organisations like SGS and Intertek conduct comprehensive chemical analyses, testing finished products for heavy metals, PFAS compounds, and other contaminants.

Consumer advocates like Lead Safe Mama use X-ray fluorescence (XRF) testing to detect lead, cadmium, and other heavy metals in cookware, publishing results publicly.

Reputable manufacturers embracing transparency willingly submit products for independent certification and openly share detailed testing reports.

When evaluating are Teflon pans are still dangerous, look for brands providing certificate of analysis documents, listing all coating components, and demonstrating compliance with standards exceeding basic legal requirements.

Red flags include vague marketing claims without supporting documentation, resistance to sharing ingredient lists, or the absence of third-party verification.

The safest approach combines selecting certified products from transparent manufacturers with proper usage practices and periodic replacement schedules that minimise accumulated exposure risks.

How to Use Non-Stick Cookware Safely

Avoid High Heat and Preheating Empty Pans

Temperature management represents the cornerstone of non-stick cookware safety.

Always use low to medium heat settings—this range provides sufficient temperature for most cooking techniques while staying well below the 500°F threshold where PTFE degradation begins.

Never preheat empty non-stick pans, as they heat rapidly without food or oil to absorb and distribute thermal energy.

An empty 8-inch pan on high heat can exceed 500°F in under three minutes, while adding just a tablespoon of oil delays reaching dangerous temperatures significantly.

Use visual and tactile cues: add a small amount of oil or butter first, and begin cooking when the fat shimmers or a water droplet sizzles gently on contact.

For techniques requiring high heat, like searing steaks or blackening fish, choose alternative cookware materials like cast iron or stainless steel that tolerate extreme temperatures without releasing fumes.

Don’t Use Metal Utensils or Abrasive Sponges

Physical protection of the coating surface directly impacts longevity and safety.

Metal utensils—spatulas, forks, tongs, whisks—create microscopic scratches that accumulate over time, eventually compromising coating integrity.

Choose wooden, silicone, or nylon utensils exclusively when cooking with non-stick surfaces.

Similarly, abrasive scrubbers, steel wool, and harsh scouring pads accelerate wear and should never contact non-stick coatings.

For stuck-on food, soak the pan in warm soapy water to loosen residue, then clean with soft sponges or microfiber cloths using gentle circular motions.

Avoid harsh chemical cleaners; mild dish soap suffices for routine cleaning.

Some cooks successfully use baking soda paste for stubborn stains, applied gently with soft cloths.

Proper cleaning protects your investment while preventing the premature damage that turns safe cookware into a replacement candidate.

Replace When Coating Peels or Discolors

Visual inspection provides clear safety indicators.

Any peeling, flaking, or chipping means immediate retirement.

Don’t attempt to salvage damaged pans by picking off loose pieces or continuing to cook in degraded areas.

Persistent discoloration, especially dark staining that doesn’t clean off, often signals chemical changes in the coating structure even when physical integrity appears intact.

Warping, which causes pans to rock on flat surfaces, creates uneven heating that accelerates coating breakdown in hot spots.

If you notice food sticking consistently in areas that previously released easily, the non-stick properties have failed, indicating underlying coating degradation.

Rather than pushing damaged cookware to total failure, proactive replacement when early warning signs appear minimises potential health exposure while maintaining cooking performance.

Quality non-stick cookware typically delivers 3-5 years of safe service with proper care; budget options may require replacement after 1-2 years.

Use Proper Ventilation During Cooking

Even when following all safety protocols, cooking generates airborne particles, steam, and volatile compounds that benefit from ventilation.

Range hoods vented to the exterior rather than recirculating models provide optimal air quality by removing cooking byproducts entirely from living spaces.

Run exhaust fans before heating begins and continue for several minutes after cooking completes, allowing complete air exchange.

If lacking mechanical ventilation, open nearby windows to create cross-ventilation during and after cooking.

This simple practice reduces the accumulation of any compounds released during cooking, whether from oils, foods, or cookware.

For households with pet birds, this precaution becomes absolutely critical, even though properly used non-stick cookware can release sufficient fumes to harm avian respiratory systems in poorly ventilated spaces.

Good ventilation practices benefit overall indoor air quality regardless of cookware choices, making this an essential kitchen safety habit worth establishing.

Safer Alternatives to Traditional Non-Stick Cookware

Ceramic Non-Stick Cookware (PTFE & PFAS-Free)

Ceramic non-stick cookware offers an appealing alternative for consumers seeking PFAS-free options without sacrificing convenience.

These products feature coatings derived from inorganic minerals (typically silicon-based) applied through sol-gel processes, creating naturally non-stick surfaces without fluorinated polymers.

The non-stick vs ceramic safety comparison favours ceramic for chemical composition—no PTFE, no PFAS, no “forever chemicals” to persist in the environment or accumulate in bodies.

However, ceramic coatings present trade-offs. They typically provide excellent initial non-stick performance but often lose effectiveness faster than quality PTFE coatings, sometimes within 1-2 years, even with careful use.

Ceramic tolerates higher temperatures without fume release concerns, though extreme heat can cause discoloration.

The coatings remain more prone to staining and may require more cooking fat than Teflon for optimal food release.

Quality varies dramatically between brands. Cheap ceramic cookware may perform poorly, while premium options from reputable manufacturers deliver satisfactory longevity and cooking experience.

Stainless Steel and Cast Iron (Natural Non-Stick Seasoning)

Stainless steel represents the workhorse of professional kitchens, prized for durability, heat tolerance, and versatility.

While not naturally non-stick, proper technique—adequate preheating, sufficient fat, and patience allowing proteins to release naturally—delivers excellent results without coating concerns.

Stainless steel requires more cooking skill and oil than non-stick alternatives but offers unparalleled longevity, oven-safety to any temperature, and compatibility with metal utensils.

Cast iron, when properly seasoned, develops a natural non-stick patina formed by polymerised oil layers bonded to the iron surface.

This seasoning improves with use, creating increasingly effective food release while adding trace iron to foods—a nutritional benefit for those at risk of deficiency.

Cast iron excels at high-heat cooking, retains heat exceptionally for even cooking, and lasts generations with minimal care.

The drawbacks include significant weight, reactivity with acidic foods that can strip seasoning, and maintenance requirements that seem daunting to beginners but become routine with familiarity.

Enamel-Coated Cast Iron (Lead-Free, Durable)

Enamel-coated cast iron combines cast iron’s excellent heat properties with a glassy, non-reactive cooking surface that doesn’t require seasoning.

The enamel coating prevents rust, allows cooking acidic foods without flavor transfer, and provides moderate non-stick properties when used with appropriate fat.

Quality enamel cookware from reputable manufacturers like Le Creuset, Staub, or Lodge uses lead-free glazes and undergoes rigorous quality testing.

However, cheaper imports occasionally contain lead or cadmium in decorative exterior glazes, making brand selection and independent verification important, particularly for brightly colored or decorative pieces.

Enamel coating can chip if dropped or subjected to thermal shock (rapid temperature changes), and once damaged, the exposed iron underneath will rust.

These pieces deliver decades of service when handled carefully, tolerate oven use to high temperatures, and transition beautifully from stovetop to table.

The investment cost exceeds most non-stick alternatives, but amortises over the extended lifespan these heirloom-quality pieces provide.

For further reading, check our guide on Enameled cast iron and Stainless steel cookware comparison.

Best PFAS-Free Cookware Brands for 2025 (GreenPan, Caraway, Xtrema, Our Place)

Several brands have distinguished themselves in the non-toxic cookware market with transparent manufacturing, third-party testing, and strong performance reputations.

GreenPan pioneered ceramic non-stick coatings with their Thermolon™ technology, offering multiple product lines at various price points with comprehensive PFAS-free certification.

Caraway combines ceramic non-stick surfaces with aluminum cores and aesthetic designs that gained popularity through direct-to-consumer marketing and genuine quality that backs up their claims.

Xtrema produces 100% ceramic cookware (body and surface) made from inorganic minerals without any metal components—completely non-toxic but requiring adjustment to the material’s unique heating properties.

Our Place offers the widely popular Always Pan featuring ceramic non-stick coating with emphasis on multifunctionality and attractive design that makes non-toxic cooking appealing to design-conscious consumers.

When selecting among alternatives, consider your cooking style, budget, and priorities regarding performance versus chemical avoidance.

Reading independent reviews and checking for certification documentation helps separate marketing claims from genuine safety innovations that justify premium pricing.

FAQs About Non-Stick Cookware Safety

No, non-stick cookware encompasses various coating technologies beyond Teflon (PTFE).

While Teflon remains the most common and recognisable non-stick coating, ceramic alternatives, silicone-based coatings, and hybrid formulations offer PTFE-free options.

When shopping, read product specifications carefully—many items marketed as “non-stick” use ceramic or other technologies specifically to avoid PTFE and PFAS compounds.

If a product doesn’t explicitly state “PTFE-free” or “PFAS-free,” assume it likely contains fluoropolymer coatings similar to traditional Teflon.

Keep non-stick cookware below 400°F (204°C) for optimal safety, with 350°F (177°C) as an ideal target for most cooking tasks.

This temperature range prevents polymer degradation while accommodating sautéing, pan-frying, and most everyday cooking techniques.

Avoid high heat settings, preheating empty pans, or any cooking method requiring searing temperatures above 450°F.

Use an infrared thermometer if uncertain about your stovetop’s output, as burner settings vary significantly between appliances and “medium” on one stove may equal “high” on another.

Some non-stick cookware tolerates oven use, but temperature limits apply.

Check manufacturer specifications—most restrict oven use to 350-400°F maximum, while handles may have lower limits if made from materials that soften or release fumes at cooking temperatures.

Never exceed stated temperature ratings, as oven environments distribute heat more evenly and intensely than stovetop cooking, increasing overheating risks.

For high-temperature baking or roasting above 400°F, choose cookware specifically designed for oven use without coating concerns—stainless steel, cast iron, or enamel-coated options handle these conditions safely.

PTFE-free means the product doesn’t use polytetrafluoroethylene (Teflon) coating, but might still contain other PFAS (per- and polyfluoroalkyl substances) in different forms.

PFAS-free indicates no fluorinated compounds whatsoever—a more comprehensive chemical exclusion.

Many ceramic non-stick products are both PTFE-free and PFAS-free, using mineral-based coatings instead.

However, some “PTFE-free” cookware may still use fluoropolymers or processing aids that fall under the broader PFAS category.

For maximum chemical avoidance, specifically seek products certified as comprehensively PFAS-free through independent testing, not just PTFE-free marketing claims that may represent narrower exclusions.

Conclusion — Non-Stick Cookware Is Safe When Used Correctly (But There Are Better Options)

Modern non-stick cookware manufactured after 2013 can be used safely when handled properly: maintaining low to medium heat, using appropriate utensils, ensuring adequate ventilation, and replacing pans at the first signs of damage.

For consumers who prioritise convenience and follow protocols diligently, quality PFOA-free non-stick cookware presents manageable risks.

However, the broader concerns about PFAS environmental persistence, potential long-term health effects, and the reality that most home cooks don’t maintain ideal usage conditions consistently justify reconsidering non-stick dependence.

The truly non-toxic cooking experience comes from PFAS-free alternatives—ceramic non-stick for easy cleanup, stainless steel for versatility and durability, or cast iron for superior heat retention and natural non-stick seasoning.

These materials eliminate chemical exposure concerns while often delivering better cooking performance and dramatically longer lifespans.

For families with young children, pregnant women, or anyone prioritising precautionary health principles, transitioning away from fluoropolymer cookware represents a worthwhile investment in long-term wellness.