Choosing lead and cadmium free dinnerware brands protects your family from hidden toxic exposure during every meal.

Heavy metals lurk in ceramic glazes, decorative patterns, and pigments used by manufacturers worldwide.

Lead and cadmium leach into food when dishes contact acidic ingredients, endure high heat, or develop surface wear over time.

Children face the greatest danger as their developing bodies absorb toxins more readily than adults.

Not all dinnerware labeled “food-safe” eliminates these metals. FDA limits still permit trace amounts that accumulate with daily use.

This guide identifies truly safe brands, explains verification methods, and clarifies material choices.

Understanding which manufacturers prioritize zero-metal formulations and submit to independent testing helps you build a kitchen free from chronic poisoning risks while maintaining the durability and aesthetics your table deserves.

Why Lead and Cadmium in Dinnerware Are a Serious Concern

What Lead and Cadmium Do to the Body

Lead targets the nervous system, creating permanent cognitive impairment even at low exposure levels.

It replaces calcium in bones, causing skeletal weakness and releasing back into the bloodstream during stress or pregnancy.

Cadmium accumulates in the kidneys, destroying filtration function and causing fatal organ failure after years of exposure.

Both metals disrupt enzyme systems throughout the body, interfering with vitamin D metabolism and iron absorption.

Unlike bacteria or viruses, these elements never break down or exit naturally. The body mistakes them for essential minerals, incorporating them into tissues where they cause oxidative damage.

Neurological effects manifest as reduced IQ, learning disabilities, and behavioral disorders that persist lifelong, making prevention through safe dinnerware the only viable protection strategy.

Why Food Contact Increases Exposure

Direct contact between meals and dishware creates the most efficient pathway for metal migration into the digestive system.

Saliva and stomach acid dissolve microscopic glaze particles that transfer during eating, delivering concentrated doses of toxins.

Unlike airborne or soil contamination that bodies can partially filter, ingested metals are absorbed directly through intestinal walls at higher rates.

The repetitive nature of meals—three times daily for decades—compounds even minimal leaching into significant lifetime exposure.

Beverages present an additional risk as hot liquids dissolve glaze faster than solid foods.

Children using the same plates for years receive exponentially higher cumulative doses than adults who rotate collections, making dinnerware safety particularly critical during developmental stages when metal toxicity causes irreversible harm.

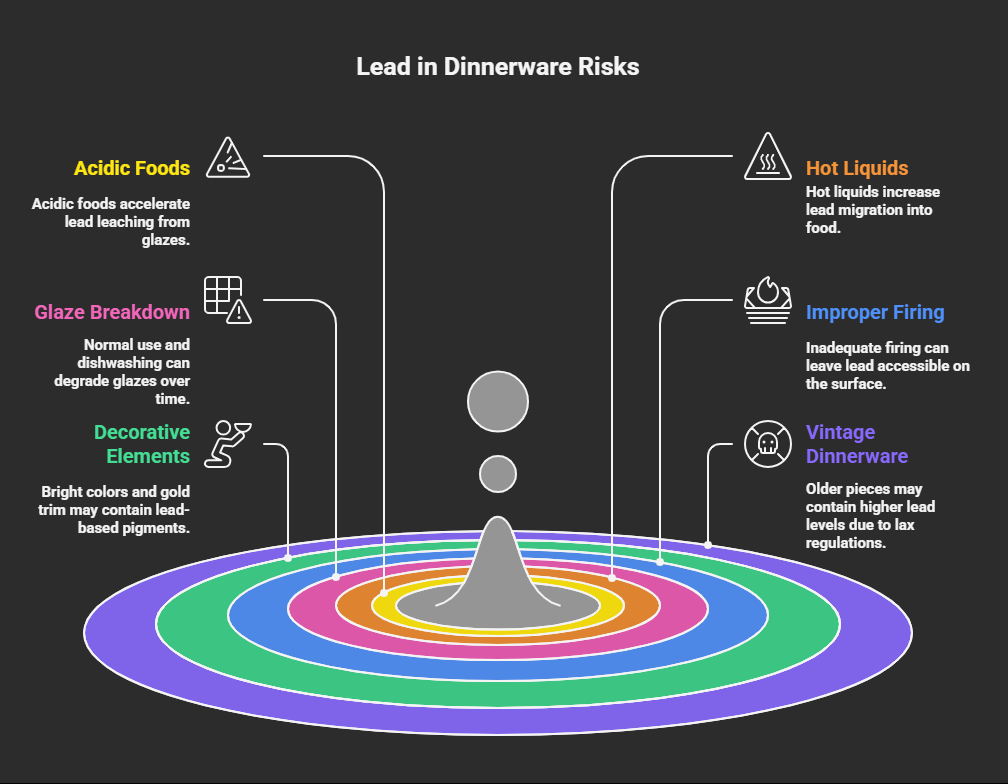

Why Heat, Acids, and Wear Increase Leaching

High temperatures break chemical bonds in ceramic glazes, releasing trapped metal particles into food.

Microwaving and dishwasher cycles subject dishes to thermal stress that degrades protective surfaces faster than handwashing.

Acidic ingredients like tomatoes, vinegar, citrus, and wine chemically react with lead-containing glazes, actively dissolving metals into meals.

The pH interaction creates ionic compounds that transfer easily across ceramic surfaces.

Physical wear from utensil scratching exposes unfinished clay beneath glazes, where manufacturers concentrate metals during firing.

Cracks and chips create direct pathways for leaching without any protective barrier.

Older dishes accumulate microscopic surface damage invisible to the eyes but catastrophic for safety, making material degradation a time-dependent risk factor regardless of original manufacturing quality or compliance.

Children and Pregnant Women at Risk

Children absorb 50% of ingested lead compared to 10% in adults due to developing digestive systems and active bone growth.

Their blood-brain barriers remain permeable longer, allowing metals direct access to neural tissue during critical formation periods.

Lead permanently lowers IQ by 3-5 points per 10 μg/dL blood concentration, with no threshold below which effects disappear.

Pregnant women transfer accumulated metals across the placenta, exposing fetuses during organ development when toxicity causes congenital defects.

Lead also contaminates breast milk, extending exposure through infancy.

Cadmium disrupts calcium absorption precisely when children need it for skeletal growth, causing brittleness and stunted development.

The vulnerability window spans conception through adolescence, making two decades of meals a critical period requiring absolutely zero-metal dinnerware for families with young members.

How Lead and Cadmium End Up in Dinnerware

Glazes and Pigments

Ceramic glazes historically relied on lead oxide as a flux that lowers firing temperatures and creates glossy finishes economically.

Cadmium produces vibrant red, orange, and yellow pigments unmatched by safer alternatives in intensity and colorfastness.

Manufacturers combine these metals with silica and other minerals to create the liquid glass coating applied before kiln firing.

The chemical reaction during heating supposedly locks metals into stable crystalline structures, but imperfect firing or formula errors leave reactive particles at the surface.

Even modern lead-free glazes sometimes contain trace contamination from shared equipment or raw material impurities.

Budget manufacturers still use leaded formulas in countries with weak regulations, then export products globally without disclosure, making glaze composition the primary contamination source in dinnerware.

Decorative Patterns and Decals

Hand-painted designs and screen-printed decals introduce concentrated metal deposits on plate surfaces where food contacts directly.

Artists traditionally mixed lead into paints for workability and color brilliance, applying thick layers that never fully integrate into the base glaze.

Decal transfers used for mass production contain metallic pigments pressed onto dishes, then fired at lower temperatures than original glazing, creating weak bonds prone to leaching.

Gold and metallic trim almost universally contain lead, making decorative edges particularly dangerous despite their small surface area.

Underglaze decorations placed before final glazing offer better safety than overglaze patterns applied after, but still risk contamination from pigment formulations.

The complexity of multi-color designs increases the likelihood of at least one problematic component, making the entire piece unsafe.

Low-Quality Manufacturing

Cost-cutting manufacturers skip proper kiln firing times or temperatures, leaving glaze incompletely vitrified with reactive metals accessible at surfaces.

They source cheap raw materials contaminated with heavy metals as unintentional impurities rather than paying premiums for purified ingredients.

Quality control testing gets omitted entirely, with no verification that finished products meet safety standards before sale.

Factories operating in regions with minimal environmental regulations discharge metal-laden wastewater that contaminates clay sources used by multiple producers.

Equipment shared between leaded and unleaded production lines cross-contaminates supposedly safe batches.

Workers without proper training apply glazes unevenly, creating thick spots that don’t fire properly.

These systemic failures plague manufacturers prioritizing profit over safety, making brand reputation and third-party verification essential purchasing criteria.

Vintage vs Modern Dinnerware

Pre-1970s dinnerware universally contains dangerous lead levels because regulations and awareness didn’t exist.

Manufacturing standards evolved slowly, with many companies continuing to use leaded formulas into the 1980s or later.

If you’re concerned about older collections, understanding vintage dish risks helps assess what needs replacement.

Modern dishes manufactured after 2000 in regulated countries generally meet current safety standards, though “modern” doesn’t guarantee safety for imports or artisan pieces.

Vintage pieces show surface wear that increases leaching exponentially compared to original condition, making age-related degradation compound initial contamination.

Collectible patterns from the mid-century often used the most problematic pigments for aesthetic appeal.

However, some vintage lines like certain Fire King pieces used naturally safe formulations, requiring individual assessment rather than blanket assumptions about age.

What “Lead and Cadmium Free” Really Means

FDA Limits vs Zero-Lead Claims

FDA regulations permit 3 ppm lead in flat dishes and 0.5 ppm cadmium, levels marketers exploit when claiming “compliant” products.

These thresholds allow measurable quantities that accumulate in bodies over lifetime exposure, not true absence.

Zero-lead claims indicate no detectable metals using standard testing methods, typically below 0.01 ppm sensitivity.

The distinction matters because daily use multiplies trace exposures into significant toxicity.

Regulatory limits protect manufacturers from liability while providing minimal consumer safety, established decades ago without modern bioaccumulation research.

Truly safe brands voluntarily meet stricter standards than the law requires, often submitting to California Proposition 65, which sets warning thresholds lower than federal limits.

Understanding this gap explains why FDA compliance offers false reassurance and why consumers need brands committed to elimination rather than minimal regulatory adherence.

“Food-Safe” vs “Lead-Free”

Food-safe certification confirms dishes won’t shatter or release chemicals at levels causing immediate harm, a low bar excluding chronic toxicity concerns.

The designation permits lead and cadmium within regulatory limits, focusing on acute rather than cumulative effects.

Lead-free specifically addresses heavy metal content, requiring absence or undetectable levels rather than mere compliance.

Manufacturers use “food-safe” to sidestep explicit metal testing while technically meeting labeling requirements.

The terminology confusion allows marketing departments to imply safety without guaranteeing it.

Consumers mistakenly assume food-safe equals non-toxic, missing the regulatory nuances that permit dangerous substances.

Savvy shoppers demand explicit lead-free and cadmium-free language backed by test results rather than accepting vague food-safe claims that obscure actual composition.

Why Trace Limits Still Matter

Bioaccumulation means microscopic daily doses compound into toxic body burdens over years of exposure.

Lead has no biological function and no safe threshold—every molecule causes harm proportional to concentration.

Children consuming three meals daily on dishes releasing 0.1 ppm lead absorb preventable neurotoxins affecting brain development.

The liver and kidneys cannot eliminate heavy metals efficiently, causing decades of accumulation from seemingly insignificant sources.

Multiple exposure pathways combine—dinnerware plus cookware plus water pipes—making each source’s contribution meaningful.

Trace limits assume single-source exposure, ignoring real-world scenarios where consumers are exposed to metals from numerous household items simultaneously.

Regulatory agencies balance industry economics against health, accepting “acceptable risk” that individuals should reject when safer alternatives exist and eliminate all avoidable exposure sources.

Marketing vs Verified Testing

Brands self-certify using internal testing without external validation, creating conflicts of interest where profit motives bias results.

Marketing departments craft language like “our process minimizes heavy metals” without quantifying actual content.

Verified testing requires independent laboratories analyzing production samples and publishing complete results, including detection limits and methodology.

Certificates of compliance represent legal documents with liability attached, not marketing fluff.

Third-party certifications from NSF International, SGS, or similar bodies confirm claims through blind testing of retail products.

Consumers should demand lab reports showing specific metal concentrations rather than accepting manufacturer assurances.

The verification gap between claimed and tested safety represents the industry’s biggest credibility problem, making transparent documentation the only trustworthy evidence of genuinely lead and cadmium free dinnerware brands.

How to Verify If a Dinnerware Brand Is Truly Safe

Third-Party Lab Testing

Independent laboratories analyze dinnerware using X-ray fluorescence or atomic absorption spectroscopy, detecting metals down to parts per billion.

These facilities have no financial stake in results, preventing the bias inherent in manufacturer self-testing.

Accredited labs follow standardized protocols that courts and regulators recognize, making reports legally defensible evidence.

Testing examines both surface and leachate, what’s present versus what transfers into food—providing complete safety pictures.

Reputable brands proactively commission testing and publish results on websites, demonstrating transparency.

Certificates of Compliance

Official certificates document that specific product lines meet defined safety standards through verified testing.

They include laboratory names, test dates, methodology details, and specific metal concentrations detected.

Legitimate certificates identify exact patterns and SKUs tested rather than vague brand-wide claims.

California Proposition 65 compliance certificates confirm products contain less than 0.5 μg lead per day of exposure, stricter than federal standards.

European Union compliance demonstrates adherence to regulations banning lead in consumer goods entirely.

Brand Transparency Pages

Trustworthy manufacturers maintain dedicated website sections explaining material sourcing, testing procedures, and safety commitments.

These pages detail where clay originates, which glaze formulas they use, and how they verify metal absence.

Specific information indicates genuine commitment—lists of avoided substances, testing frequency schedules, and laboratory partner names.

Vague statements like “we follow all regulations” signal minimal compliance rather than excellence.

Transparency includes admitting when products contain trace elements and explaining why levels remain safe.

Independent Testing Kits

Home test kits like LeadCheck swabs provide preliminary screening by changing color when detecting lead above 2 ppm.

These tools help identify obviously contaminated dishes, but can’t quantify exact amounts or detect cadmium reliably.

False negatives occur when metals concentrate beneath surfaces or in glazes that don’t react with test chemicals.

You can explore various home test kits to understand their capabilities and limitations.

XRF analyzers offer more accuracy for $500-2000, measuring precise metal content through handheld devices.

Testing multiple spots on each dish captures variability in glaze application and decoration.

Best Lead and Cadmium Free Dinnerware Brands

Corelle

Corelle manufactures dishes from Vitrelle glass, a proprietary three-layer tempered material containing no ceramic components requiring glaze.

The glass composition inherently excludes lead and cadmium, used in traditional pottery glazing processes.

However, some Corelle patterns with lead exist in older decorated lines where screen-printed designs introduced metals, though post-2000 collections eliminated these.

Despite past Corelle’s rumored recalls, the base material remains naturally safe. Third-party testing confirms undetectable metal levels in white and modern printed patterns.

The material’s density prevents leaching even if contamination existed because glass doesn’t degrade like ceramic glazes.

Lightweight construction makes handling easy while tempered layers resist breaking and chipping that expose interior materials.

When disposing of Corelle with lead, focus on vintage decorated patterns while keeping plain modern pieces.

Fiesta (Post-1986 Only)

Fiestaware manufactured before 1986 contained radioactive uranium oxide for red-orange glazes, also introducing lead contamination.

The company reformulated entirely after production resumed, eliminating all heavy metals and radioactive materials from modern color palettes.

Current Fiestaware lead-free formulations undergo rigorous testing, meeting California Proposition 65 standards.

The brand publishes detailed safety information on its website, including specific test results for each color.

Lead-free pigments now create the signature bright hues through titanium and iron oxides instead of cadmium.

All manufacturing occurs in the USA under strict regulatory oversight. The company maintains transparent communication about vintage versus modern safety, helping consumers distinguish problematic vintage pieces from current safe inventory.

Xtrema

Xtrema produces 100% ceramic cookware and dinnerware using proprietary formulations explicitly tested and certified lead and cadmium free.

The company provides comprehensive lab reports on their website showing testing methodology and undetectable metal results.

All manufacturing occurs under controlled conditions with quality assurance testing on production batches.

The ceramic material withstands high temperatures and thermal shock while maintaining aesthetic appeal.

Xtrema markets specifically to health-conscious consumers, making safety claims central to brand identity and subject to higher scrutiny.

IKEA (Select Lines)

IKEA operates under strict European Union regulations that ban lead in consumer products entirely, creating baseline safety for EU-manufactured items.

However, IKEA lead free status varies by product line and manufacturing origin. The company publishes chemical policy documents detailing restricted substances and testing procedures.

Not all IKEA dinnerware comes from EU factories—some lines are manufactured in Asia with different standards requiring line-specific verification.

Plain white porcelain collections typically test clean, while decorated pieces need individual assessment. IKEA’s transparency allows consumers to review the country of origin and request safety documentation before purchase.

The affordability makes them accessible for families replacing contaminated dishes on a budget.

Always verify specific collections meet lead-free standards rather than assuming brand-wide safety.

Anchor Hocking and Arc International

Anchor Hocking produces glass dinnerware inherently free from heavy metals due to material composition, requiring no glazing.

The clear glass manufacturing process uses sodium, calcium, and silica without lead or cadmium additives.

Arc International similarly makes Luminarc lead-free options, and Duralex lead-free products from tempered glass that naturally exclude toxic metals.

These brands offer transparent material safety because glass composition doesn’t hide contaminants beneath decorative layers.

The durability of tempered glass matches that of ceramic while eliminating glaze-related concerns.

Both companies manufacture primarily in regulated markets with transparent supply chains.

Glass dinnerware from these manufacturers provides reliable safety across entire product lines without requiring pattern-specific verification, simplifying purchasing decisions for consumers prioritizing guaranteed metal-free options.

Safest Materials for Lead and Cadmium Free Dinnerware

Glass (Naturally Lead-Free)

Glass dinnerware eliminates lead contamination risks, as it contains no ceramic components requiring lead-based glazes.

Made from melted silica, sodium carbonate, and limestone, glass creates a chemically inert material that never leaches metals.

Unlike ceramics with variable glaze safety, glass composition stays consistent across all brands.

Its transparency confirms material purity, no hidden coatings or contaminants.

Glass resists acids, withstands repeated dishwasher cycles, and prevents bacterial growth in microcracks that develop in porous ceramics.

For guaranteed lead and cadmium absence, glass is the safest dinnerware choice, requiring no testing or brand verification.

Plain White Porcelain

Undecorated white porcelain typically uses clear glazes without metal-contaminating pigments, reducing contamination risks compared to colored pieces.

High-quality porcelain fired at 1300°C creates vitrified, non-porous surfaces. Many manufacturers prioritize safety for plain white lines targeting health-conscious consumers.

However, “white” doesn’t guarantee safety—budget producers may still use lead-containing glazes.

Modern lead-free porcelain from reputable manufacturers offers excellent safety when verified.

Restaurant-grade white porcelain often exceeds residential standards due to commercial liability concerns, making hotel supply brands reliable choices.

High-Fired Ceramic with Tested Glaze

Ceramics fired above 1200°C vitrify completely, creating dense material where glazes bond permanently without leaving reactive metals accessible.

High temperatures ensure complete chemical reactions, locking metals into stable crystalline structures.

However, high firing doesn’t eliminate contamination if manufacturers use leaded glazes—third-party testing remains essential.

Quality stoneware and porcelain manufactured with lead-free formulations achieve safety.

High-fired ceramics resist crazing and surface degradation that increases leaching over time.

Some artisan potters combine high-temperature firing with metal-free glazes for safety. Properly manufactured pieces maintain durability and safety throughout their extended lifespan.

Stainless Steel (Kids Plates)

Stainless steel contains no lead or cadmium, offering absolute safety for children’s dinnerware.

The alloy uses iron, chromium, and nickel without toxic additives. Manufacturing involves no glazing process, eliminating primary contamination risks.

Its durability prevents breaking, sharp edges, and waste, making it economical and eco-friendly.

Stainless steel withstands drops and dishwasher cycles without degradation or leaching. Testing isn’t necessary—the material guarantees safety.

Divided plates and bowls combine functionality with chemical inertness. The only consideration is nickel allergies affecting small user percentages, unrelated to lead concerns.

Dinnerware Types That Carry Higher Lead Risk

Vintage or Antique Dishes

Pre-1980s ceramics universally used lead-based glazes as the industry standard, making vintage collections dangerous regardless of brand or condition.

Mid-century decorative patterns contained extremely high cadmium levels for vibrant colors.

Manufacturing lacked safety testing or contamination awareness. Even premium manufacturers produced problematic pieces.

Surface wear from decades increases leaching as glazes erode. Antique dishes should never contact food—display-only use preserves heirlooms safely.

Testing vintage pieces reveals lead levels hundreds of times above modern standards, making disposal or repurposing the only safe approach.

Hand-Painted Ceramics

Artisan pottery often uses lead-containing paints and glazes for workability and color intensity.

Small studios lack testing budgets and regulatory oversight, increasing contamination risks.

Artists trained before modern safety awareness may use traditional techniques with dangerous materials.

Hand-applied glazes create inconsistent firing, where some areas vitrify while others expose reactive metals.

Handmade pieces’ appeal—bright colors and artistic patterns—often indicates problematic pigments.

Without explicit lead-free certification and testing documentation, hand-painted ceramics pose a significant risk.

Many cottage industry creators remain unaware of contamination dangers, innocently producing unsafe products for health-conscious consumers.

Bright Red, Orange, Yellow Glazes

Red, orange, and yellow colors historically required cadmium-based pigments, unmatched by safer alternatives for intensity and colorfastness.

These glazes still present the highest contamination risk due to technical and economic formulation challenges.

Yellow ceramics frequently contain cadmium sulfide, producing vibrant hues impossible with alternatives.

Modern pieces in these colors warrant additional scrutiny and testing. Some countries with weaker regulations continue using traditional cadmium formulations.

Brands achieving safe, bright colors through expensive alternatives typically advertise this specifically.

Cautious consumers should avoid or test these shades, particularly in imported or budget products where safety shortcuts commonly occur.

Imported Unregulated Products

Countries without stringent consumer protection laws allow manufacturers to use lead and cadmium freely, reducing costs.

Imported ceramics from weak-enforcement regions arrive without testing or safety documentation.

Language barriers and complex supply chains obscure manufacturing practices. Budget imports use toxic but economical metal-based glazes.

Some nations lack testing infrastructure, preventing manufacturer verification. Artwork and decorative dishes enter customs with minimal scrutiny.

Consumers unknowingly purchase highly contaminated ethnic or artisan imports.

While many USA-made non-toxic brands provide safer alternatives, the global marketplace makes avoiding imports difficult without diligent origin and testing verification.

Lead and Cadmium Free Dinnerware for Kids

Why Children Absorb More Lead

Children’s developing digestive systems absorb 40-50% of ingested lead compared to adults’ 10%, making identical exposure far more dangerous.

Their growing brains remain vulnerable to neurotoxic effects throughout childhood when neural connections form most rapidly.

Hand-to-mouth behavior and floor play increase exposure frequency beyond mealtimes.

Lead replaces calcium in growing bones, where it is stored for decades, releasing during pregnancy to affect future generations.

Childhood metal exposure permanently reduces lifetime cognitive potential, making kid-specific dinnerware safety non-negotiable.

Best Materials for Kids

Stainless steel plates and bowls eliminate all leaching concerns while withstanding drops and rough handling typical of young children.

Tempered glass from brands like Corelle offers break resistance with guaranteed material safety.

Plain white porcelain from verified manufacturers provides traditional aesthetics with confirmed metal absence.

Silicone dining products from food-grade manufacturers avoid both heavy metals and breakage injuries, though some parents question plastic-alternative safety profiles.

Bamboo fiber plates marketed for children require verification of the binding agents and coatings used.

Avoiding Plastic and Melamine

While lead and cadmium rarely appear in plastic dinnerware, these materials introduce different concerns, like BPA, phthalates, and formaldehyde, that similarly disrupt development.

Melamine-based children’s plates leach toxic compounds when heated or scratched, particularly dangerous for microwave use.

The broader category of “non-toxic” encompasses more than heavy metals, making plastic alternatives imperfect solutions when replacing contaminated ceramic dishes.

Hot foods accelerate chemical leaching from plastics, making them particularly inappropriate for children’s meals.

Lead-Free vs Non-Toxic Dinnerware — Are They the Same?

Heavy Metals vs PFAS and Coatings

Lead-free certification addresses only heavy metal content, ignoring fluorinated compounds, plasticizers, and synthetic coatings present in modern materials.

PFAS (per- and polyfluoroalkyl substances) appear in some ceramic non-stick coatings and plastic dinnerware, creating hormone disruption and cancer risks distinct from metal toxicity.

Antimicrobial coatings added to children’s products sometimes contain silver nanoparticles or triclosan with unknown long-term effects.

Synthetic pigments and dyes used in decorations may comply with heavy metal regulations while introducing entirely different chemical hazards.

Consumers seeking truly safe dinnerware must ask about all chemical additives, not just regulated heavy metals, to avoid replacing one hazard with another.

Broader Definition of Non-Toxic

Non-toxic encompasses the absence of any substance causing harm through normal use, extending beyond lead and cadmium to hundreds of potential contaminants.

It includes evaluation of manufacturing byproducts, cleaning agent residue, and packaging materials that might transfer to finished products.

The term considers endocrine disruptors, carcinogens, neurotoxins, and reproductive toxins across all chemical categories.

Truly non-toxic products avoid plastic components with phthalates and BPA, radioactive materials, and volatile organic compounds.

Lead-free represents one component of non-toxic, but doesn’t guaranteethe absence of other harmful substances, making comprehensive safety claims require broader testing and disclosure than single-category certifications provide.

Why Both Matter

Focusing exclusively on heavy metals while ignoring other contaminants creates false security about overall product safety.

Modern manufacturing introduces synthetic chemicals unknown during earlier eras when lead dominated toxicity concerns.

Replacing leaded ceramic with plastic alternatives trades known neurotoxins for endocrine disruptors with equally serious long-term health consequences.

The complex chemical landscape means truly safe dinnerware requires evaluating material composition holistically rather than checking individual hazard boxes.

Lead and cadmium absence remains critical but insufficient for comprehensive safety, particularly for children whose developing systems remain vulnerable to multiple toxicity mechanisms.

FAQ — Lead and Cadmium Free Dinnerware

No. Modern manufacturing in unregulated countries still uses lead-based glazes for cost savings.

Even regulated markets permit trace amounts under compliance thresholds. Imported products often lack testing verification regardless of the manufacturing date.

Decorative elements introduce contamination even when base materials meet standards.

Always verify specific brands through documentation rather than assuming manufacturing date guarantees safety.

Generally, yes, but not guaranteed. White pieces typically avoid pigments containing cadmium and decorative elements introducing lead.

However, some manufacturers still use lead in clear glazes on white ceramics. Plain white reduces variables but doesn’t eliminate the possibility.

Third-party testing remains necessary even for simple white pieces from unknown manufacturers to confirm the actual metal.

Yes significantly. High temperatures and harsh detergents degrade protective glaze surfaces, exposing reactive underlayers.

Thermal cycling creates microcracks, allowing metal migration into food contact areas.

Older dishes show exponentially higher leaching after repeated dishwasher use compared to new conditions.

Surface etching from prolonged dishwasher exposure breaks down bonds, keeping metals locked in the ceramic structure.

Hand-washing extends the safety of marginal pieces.

No, FDA limits permit measurable lead and cadmium leaching that accumulates over lifetime use.

Compliance represents minimum legal requirements, not optimal health standards.

The 3 ppm lead limit allows chronic exposure affecting children’s development.

California Proposition 65 sets stricter thresholds, better protecting consumers.

Truly safe brands exceed FDA minimums by eliminating detectable metals entirely rather than meeting only mandatory compliance levels.

Final Verdict — Choosing Truly Safe Dinnerware Brands

Protecting your family requires moving beyond marketing claims to verified documentation of metal absence.

Prioritize brands providing third-party lab results showing undetectable lead and cadmium levels across production batches.

Glass and stainless steel offer inherent safety requiring no verification, while ceramic and porcelain demand rigorous testing and proof regardless of claims.

Avoid vintage dishes, hand-painted pieces, and bright-colored glazes unless testing confirms safety.

Replace worn dinnerware showing cracks, chips, or surface degradation that increases leaching exponentially.

For children’s dishes, choose only materials with absolute certainty of safety; their vulnerability justifies zero-risk approaches.

Request certificates of compliance before purchasing and verify certificate authenticity directly with testing laboratories.

Building a lead and cadmium free dinnerware collection protects neurological health, prevents organ damage, and eliminates a major chronic exposure source affecting quality of life for decades.