Choosing between non-stick vs enamel cookware isn’t just about convenience; it’s about your family’s health, your cooking style, and how long you want your investment to last.

Every morning, millions of homes reach for a pan without considering what’s happening beneath the surface.

Is that slick coating releasing invisible fumes? Could that colorful enamel contain hidden toxins?

These aren’t just hypothetical concerns. The cookware you use daily directly impacts the safety of your meals, the flavors you create, and even the environment.

Both non-stick and enamel cookware promise easier cooking and cleanup, but they deliver these benefits in fundamentally different ways.

One relies on synthetic polymer technology that has sparked decades of health debates.

The other uses centuries-old glass-fusion techniques that stand the test of time.

Understanding which is safer, enamel or non-stick, requires looking beyond marketing claims to examine the science, the materials, and the real-world performance of each option.

This comprehensive guide will help you make an informed decision based on facts, not fear.

What Is Non-Stick Cookware?

Non-stick cookware revolutionized home cooking by preventing food from sticking to the pan surfaces.

At its core, this cookware type features a base metal—typically aluminum—coated with a synthetic polymer layer that creates a slippery cooking surface.

The technology allows you to cook with minimal oil while making cleanup remarkably easy.

PTFE (Teflon) Coating Explained

Polytetrafluoroethylene, commonly known as Teflon, is the most recognized non-stick coating material.

This fluoropolymer creates an extremely low-friction surface by forming molecular bonds that repel water, oil, and food particles.

The coating is applied in multiple layers to aluminum or stainless steel bases through a process involving primer coats and topcoats that are baked at high temperatures.

Presence of PFAS, PFOA (Older Pans), GenX

PTFE belongs to a chemical family called per- and polyfluoroalkyl substances (PFAS), often called “forever chemicals” because they don’t break down naturally.

While PTFE itself is considered stable at normal cooking temperatures, the manufacturing process historically used PFOA (perfluorooctanoic acid), which has been linked to health concerns.

Since 2013, major manufacturers have phased out PFOA, but replacement chemicals like GenX have raised similar questions.

Modern non-stick pans are marketed as PFOA-free, yet they still contain PFAS compounds.

Aluminum Base + Layered Polymer Coating

The typical construction includes an aluminum core for excellent heat conduction, covered by multiple polymer layers.

The aluminum provides lightweight handling and responsive heating, while the coating layers—primer, midcoat, and topcoat—create the non-stick properties.

Some premium versions incorporate titanium or diamond particles for enhanced durability, but the fundamental chemistry remains PTFE-based.

Pros and Cons for Everyday Cooking

Pros:

- Requires minimal cooking oil or butter

- Easy cleanup with simple wiping

- Lightweight and easy to handle

- Affordable entry-level options available

Cons:

- Coating degrades over time (1-3 years typical lifespan)

- Cannot withstand high heat without potential fume release

- Scratches easily with metal utensils

- Raises concerns about PFAS exposure

Learn the full safety profile of non-stick pans to understand the complete picture of what you’re cooking with daily.

What Is Enamel Cookware?

Enamel cookware represents one of the oldest and most reliable cooking technologies, dating back centuries.

Unlike synthetic coatings, enamel is created by fusing powdered glass to metal surfaces at extremely high temperatures, creating a smooth, non-porous, and chemically inert cooking surface.

Glass Enamel Fused to Cast Iron or Steel

The enameling process involves applying multiple layers of ground glass mixed with metallic oxides to cast iron or carbon steel bases.

These pieces are fired in kilns at temperatures exceeding 1,400°F, causing the glass to melt and bond permanently with the metal substrate.

This fusion creates a coating that becomes an integral part of the cookware rather than a temporary surface layer.

Inert, PFAS-Free, and Chemically Stable

Enamel cookware contains no synthetic polymers, making it completely PFAS-free.

The glass surface is chemically inert, meaning it won’t react with acidic foods like tomatoes or wine.

This stability prevents any leaching of chemicals into your food, regardless of cooking temperature or duration.

The coating won’t break down from heat, making it fundamentally different from polymer-based alternatives when considering enamel cookware vs non-stick safety.

Vintage vs Modern Enamel Pigment Safety

Older enamel cookware, particularly pieces manufactured before 1980, may contain lead or cadmium in decorative colored glazes.

These heavy metals were used to create vibrant colors but pose health risks if they leach into food.

Modern enamel cookware from reputable manufacturers complies with strict safety standards and uses lead-free, cadmium-free pigments.

However, vintage pieces and products from unregulated manufacturers still warrant caution.

You can test enamel cookware for heavy metals if you’re uncertain about older pieces.

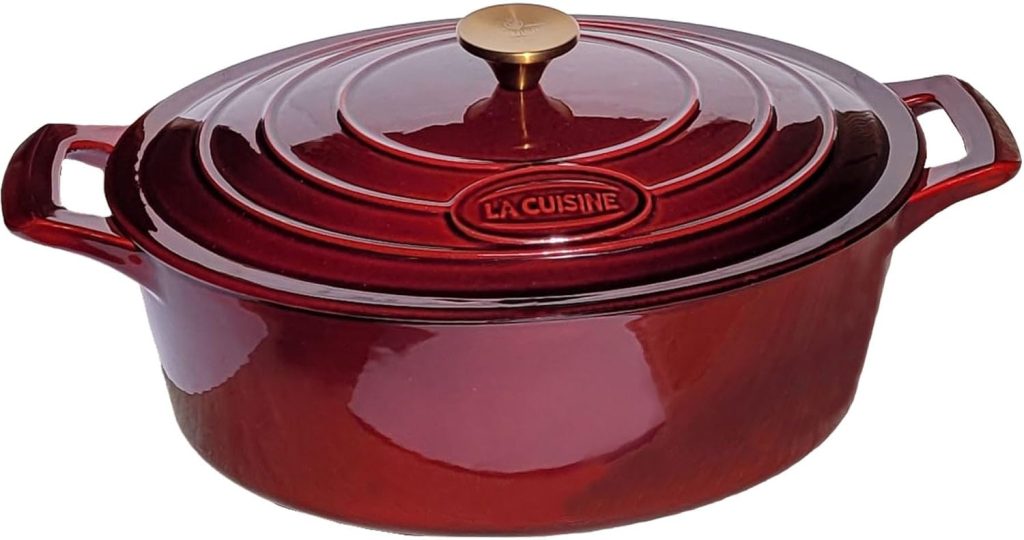

Popular Enamel Cookware Brands

Leading enamel cookware manufacturers include Le Creuset, Staub, Lodge, and Cuisinart.

These brands have established reputations for quality control and safety compliance.

Le Creuset and Staub represent premium options with lifetime warranties, while Lodge offers more budget-friendly alternatives.

Each brand undergoes rigorous testing to ensure its enamel coatings meet FDA and California Prop 65 standards.

To fully understand the safety protocols, see enamel safety testing & modern standards that protect consumers.

Key Differences Between Non-Stick and Enamel Coatings

Understanding the fundamental differences between these two coating technologies helps clarify why they perform so differently in real-world cooking scenarios.

Synthetic Polymer vs Glass-Based Coating

Non-stick coatings are manufactured chemical compounds applied to metal surfaces, while enamel is melted glass permanently fused to metal.

This distinction matters because synthetic polymers are organic compounds that can degrade, while glass is an inorganic material that remains stable indefinitely.

The molecular structure of PTFE consists of carbon-fluorine bonds that can break under certain conditions, whereas enamel’s silicon-oxygen bonds are among the strongest in chemistry.

Non-Stick Functionality

Despite its name, enamel cookware isn’t as inherently non-stick as PTFE-coated pans.

Non-stick cookware releases eggs and delicate proteins with minimal effort, even when using little to no oil.

Enamel cookware requires proper preheating and adequate fat for optimal food release.

However, enamel develops better over time as a cooking patina forms, and it allows for deglazing and fond development that actually enhances flavor, something non-stick surfaces prevent.

Weight Differences

Non-stick pans are notably lighter, typically weighing 1.5-3 pounds for a standard skillet, thanks to their aluminum construction.

Enamel cookware, especially enameled cast iron, weighs significantly more—often 5-8 pounds for comparable sizes.

This weight difference affects handling ease, especially for elderly users or those with limited strength.

The enameled cast iron vs stainless steel comparison reveals additional weight and performance factors.

Base Metal Differences (Aluminum vs Cast Iron/Steel)

Aluminum heats quickly but doesn’t retain heat well, making it responsive but less suitable for sustained cooking.

Cast iron and steel bases in enamel cookware heat more slowly but maintain temperature exceptionally well, perfect for braising and slow-cooking applications.

This fundamental material difference means each cookware type excels in different cooking techniques.

Safety Comparison — PFAS, Lead & Chemical Exposure

Safety concerns drive much of the comparison in nonstick vs enamel durability and overall cookware selection. Let’s examine the specific risks associated with each type.

PFAS & Off-Gassing at High Temps (Non-Stick)

Does non-stick release fumes? Yes, when overheated above 500°F, PTFE coatings begin breaking down and releasing toxic fumes.

These fumes can cause polymer fume fever in humans, with flu-like symptoms including headaches, chills, and respiratory irritation.

The fumes are particularly dangerous to pet birds, which have sensitive respiratory systems.

Even at lower temperatures, gradual PFAS release may occur as coatings degrade through normal use.

Teflon Flaking or Scratching Risks

When non-stick coatings scratch or chip, microscopic particles can end up in food.

While manufacturers claim these particles pass harmlessly through the digestive system, the long-term effects of ingesting PFAS-containing fragments remain uncertain.

Scratched pans also lose their non-stick properties and heat less evenly, creating hot spots that further accelerate coating breakdown.

Enamel & Heavy Metal Concerns (Rare, Mainly Vintage)

Is enamel cookware non-toxic? Modern enamel cookware from reputable brands is extremely safe and contains no lead or cadmium.

However, vintage pieces, especially those with bright exterior colors or decorative patterns, may contain these heavy metals in the glaze formulations.

The risk primarily exists with older cookware or pieces from manufacturers who don’t follow current safety standards.

Modern Enamel Safety Standards (Prop 65, FDA Compliant)

Contemporary enamel cookware manufacturers must comply with FDA regulations and California Proposition 65, which sets strict limits on lead and cadmium content.

Reputable brands conduct regular third-party testing and publish certificates of compliance.

These standards make modern enamel cookware one of the safest options available.

For those seeking a PFAS-free alternative to Teflon, certified enamel cookware offers peace of mind without sacrificing cooking performance.

Heat Performance & Cooking Experience

How each cookware type handles heat dramatically affects what you can cook and how well dishes turn out.

Non-Stick – Great for Eggs, Delicate Foods

Non-stick cookware excels at low-to-medium heat cooking applications.

Scrambled eggs slide effortlessly from the pan, fish fillets release cleanly, and pancakes flip without tearing.

The slick surface requires minimal fat, making it ideal for health-conscious cooking.

However, this advantage disappears when you need high-heat searing or want to develop fond for pan sauces.

Enamel – Great for Stews, Braising, Slow Cooking

Enamel cookware shines in applications requiring sustained, even heat.

Dutch ovens braise short ribs to perfection, maintaining steady temperatures for hours.

The non-reactive surface won’t alter the flavor of acidic ingredients, making it perfect for tomato-based sauces and wine reductions.

The heavy construction provides superior heat retention, keeping soups and stews at consistent temperatures.

Heat Tolerance Comparison (500°F vs >1000°F for Enamel)

Non-stick pans should never exceed 500°F—a temperature easily reached on stovetops at medium-high settings.

Above this threshold, coating degradation accelerates, and toxic fumes may be released.

Enamel cookware, by contrast, can withstand temperatures exceeding 1,000°F without damage, making it oven-safe at any home cooking temperature.

This makes enamel vs non-stick for high-heat cooking an easy decision for serious home cooks.

Which Performs Better for High-Heat Cooking? → Enamel

For searing steaks, roasting at high temperatures, or any technique requiring sustained high heat, enamel cookware is the clear winner.

The glass coating remains stable and intact regardless of temperature, while the cast iron or steel base delivers exceptional heat retention.

Non-stick simply cannot compete in high-heat scenarios without risking coating damage and potential health concerns.

Durability & Lifespan Comparison

The longevity of cookware directly impacts both your budget and environmental footprint over time.

Scratch Resistance (Enamel Wins)

Enamel’s glass surface is significantly harder than PTFE coatings, offering superior scratch resistance.

While you should still avoid metal utensils and abrasive scrubbers, enamel tolerates moderate wear far better than non-stick.

PTFE coatings scratch easily from metal spatulas, rough sponges, or even stacking pans without protection.

These scratches compromise the non-stick properties and accelerate coating failure.

Chipping (Enamel Risk) vs Peeling (Non-Stick Risk)

Enamel cookware’s primary vulnerability is chipping from impact—dropping a pot or banging it against hard surfaces can crack the glass coating.

Once chipped, the exposed metal underneath may rust if not properly maintained.

Non-stick coatings face peeling issues as the polymer layers separate from the base metal through thermal cycling and general use.

Both problems render the cookware less effective, but enamel damage is typically localized while non-stick degradation spreads across the entire surface.

Expected Lifespan (Non-Stick: 1–3 Years, Enamel: Decades)

Even with careful use, non-stick cookware typically lasts only 1-3 years before the coating degrades noticeably.

Professional chefs may replace non-stick pans annually.

Quality enamel cookware, however, can last decades or even become family heirlooms.

Many homes use the same Le Creuset Dutch oven for 20-30 years with proper care. This longevity consideration is central to understanding nonstick vs enamel durability.

Long-Term Cost-Effectiveness

While enamel cookware requires a larger upfront investment ($50-$400 per piece), its decades-long lifespan makes it more economical over time.

Replacing non-stick pans every 2-3 years at $30-$80 each adds up significantly.

A $200 enameled Dutch oven that lasts 25 years costs $8 per year, while a $40 non-stick pan replaced every 2 years costs $20 annually, plus the hassle of repeated shopping.

Maintenance & Care Differences

Proper care extends cookware life and maintains optimal performance, but the requirements differ substantially between these two types.

Cleaning Non-Stick (Hand Wash Only, Avoid Abrasives)

Non-stick cookware demands gentle hand washing with soft sponges and mild dish soap.

Never use abrasive scrubbers, steel wool, or harsh cleaners that will scratch the coating.

Most food residue wipes away easily, but stuck-on food should be soaked rather than scrubbed aggressively.

Dishwashers, despite some manufacturers’ claims, typically shorten non-stick coating lifespan through harsh detergent exposure and high heat.

Cleaning Enamel (Soaking, Non-Abrasive Scrubs)

Enamel cookware tolerates more vigorous cleaning than non-stick, but still benefits from gentle treatment.

Soaking stubborn residue makes cleaning easier and prevents the need for excessive scrubbing.

Non-abrasive scrubbers work well for stuck-on food, and many enameled pieces are dishwasher-safe, though hand washing preserves exterior finishes better.

Baking soda paste effectively removes stains without damaging the glass surface.

The ceramic vs stainless steel cookware comparison provides additional context on maintenance requirements for different materials.

Utensil Compatibility

Non-stick cookware requires silicone, wooden, or plastic utensils exclusively.

Metal spatulas, whisks, and spoons will scratch the coating, compromising both non-stick properties and safety.

Enamel cookware accepts wooden and silicone utensils safely and tolerates occasional metal utensil use, though wood and silicone remain preferable to prevent potential chipping.

This flexibility makes enamel more practical for diverse cooking techniques.

Dishwasher Safety for Each

Most non-stick manufacturers recommend hand washing only, as dishwasher detergents and high heat accelerate coating breakdown.

Some newer “dishwasher-safe” non-stick pans exist, but longevity still suffers compared to hand washing.

Enamel cookware typically handles dishwashers well, though the exterior finish may dull over time.

Interior enamel surfaces remain unaffected by dishwasher use, making cleanup more convenient.

Environmental Impact

Cookware choices affect not just your kitchen but the broader environment through manufacturing processes and disposal.

PFAS Persistence & Non-Biodegradable Waste (Non-Stick)

PFAS chemicals earned the nickname “forever chemicals” because they don’t break down naturally in the environment.

When non-stick pans end up in landfills, these persistent compounds can leach into soil and water systems, remaining there indefinitely.

Manufacturing PFAS also creates environmental contamination around production facilities.

The short lifespan of non-stick cookware means more frequent disposal, multiplying the environmental burden.

Enamel’s Recyclability and Long Lifespan

While enamel cookware isn’t directly recyclable due to the glass-metal fusion, its decades-long lifespan dramatically reduces waste generation.

The cast iron or steel bases theoretically can be recycled if the enamel coating is removed, though this isn’t commonly done.

More importantly, enamel cookware rarely needs disposal; it’s often passed down through generations, making it one of the most sustainable cookware options through longevity alone.

Manufacturing Impacts

PTFE production involves complex chemical processes with significant environmental footprints, including greenhouse gas emissions and chemical waste.

Enamel manufacturing also requires high-temperature kilns consuming substantial energy, but the process avoids persistent chemical production.

Cast iron production is energy-intensive but uses abundant natural materials.

Overall environmental impact depends on usage duration; enamel’s longevity tips the balance in its favor.

Which Produces Less Waste Over Time? (Enamel)

Enamel cookware unquestionably generates less waste over a lifetime.

One enameled Dutch oven serving 25 years replaces a dozen non-stick pans in the same period.

This waste reduction includes not just the pans themselves but also packaging, shipping impacts, and disposal costs.

For environmentally conscious consumers, the choice between enamel vs non-stick becomes clear when considering long-term environmental responsibility.

Which Should You Choose?

The right choice depends on your cooking style, health priorities, and practical considerations rather than a universal “best” option.

Choose Enamel If You Want Durability & Safety

Enamel cookware suits cooks prioritizing long-term value, health safety, and versatile cooking techniques.

If you regularly braise, make soups and stews, or prepare acidic dishes, enamel’s non-reactive surface and heat retention make it ideal.

Home cooks willing to invest upfront for decades of use will find enamel’s durability and PFAS-free composition compelling.

The weight requires consideration, but for most cooking tasks, enamel delivers superior performance.

Choose Non-Stick for Convenience & Low-Oil Frying

Non-stick remains the practical choice for quick breakfast cooking, delicate proteins, and low-fat meal preparation.

If you primarily cook eggs, pancakes, or fish at low to medium temperatures, non-stick’s ease of use and cleanup may outweigh long-term concerns.

Budget-conscious cooks willing to replace pans every few years can benefit from non-stick’s affordability and lightweight handling.

Best Cookware for a Toxin-Free Kitchen → Enamel

For those committed to eliminating potential toxins from their cooking environment, enamel cookware is the superior choice.

Its PFAS-free, chemically inert surface eliminates concerns about fume release or chemical leaching.

Modern enamel from reputable brands contains no lead or cadmium, providing peace of mind that your cookware contributes nothing unwanted to your meals.

When comparing ceramic and non-stick coatings, enamel often emerges as the safest long-term option.

Best for Elderly or Disabled Users → Lightweight Non-Stick

Users with limited strength, arthritis, or mobility challenges may find non-stick cookware’s lightweight construction essential.

A 2-pound non-stick skillet is far easier to maneuver than a 7-pound enameled cast-iron pan.

For these users, the convenience and manageable weight of non-stick cookware may outweigh other considerations, making it a practical accessibility choice.

FAQs About Non-Stick vs Enamel Cookware

Which is more non-stick?

PTFE-coated non-stick cookware offers superior food release, especially when new.

Enamel cookware requires proper preheating and adequate cooking fat, but develops improved release properties with use.

For true minimal-oil cooking of eggs and delicate proteins, non-stick wins this category.

Does enamel ever contain lead?

Modern enamel cookware from reputable manufacturers contains no lead or cadmium and complies with FDA and Prop 65 standards.

However, vintage pieces (pre-1980s) and cookware from unregulated sources may contain lead in colored glazes.

Always verify compliance certifications or test vintage pieces before use.

Is non-stick safe if used on low heat?

Using non-stick cookware exclusively on low to medium heat (below 400°F) significantly reduces risks.

However, coating degradation still occurs gradually over time through normal use, and PFAS remain present in the material even when not actively releasing fumes.

Proper ventilation and replacing pans when coatings show wear minimizes potential exposure.

Which cookware lasts longer?

Enamel cookware dramatically outlasts non-stick, often by decades.

Quality enameled cast iron can serve 20-30 years or more with proper care, while even premium non-stick pans typically need replacement within 3-5 years.

This lifespan difference makes enamel far more cost-effective and sustainable long-term.

Final Verdict — Enamel Is Safer, Non-Stick Is More Convenient

The choice between non-stick and enamel cookware ultimately balances safety, durability, and cooking convenience against immediate ease of use and upfront costs.

Non-stick cookware delivers unmatched convenience for quick, low-fat cooking of delicate foods, but its PTFE-based coating raises legitimate health concerns, particularly regarding PFAS exposure and high-heat degradation.

The limited 1-3 year lifespan also creates ongoing replacement costs and environmental waste.

Enamel cookware represents the superior long-term investment for most homes.

Its PFAS-free, chemically inert glass coating provides genuine safety for all cooking temperatures while lasting decades with proper care.

Though heavier and requiring more cooking fat, enamel excels at techniques like braising, slow cooking, and high-heat searing that non-stick simply cannot handle safely.

For health-conscious cooks building a toxin-free kitchen, high-quality enamel cookware from certified manufacturers offers unmatched peace of mind and lifetime value.

Finally, we invite you to explore the best PFAS-free and enamel cookware brands that combine safety, performance, and lasting durability.