Heat resistant glassware has become essential in modern kitchens, but not all glass can handle thermal stress equally.

Understanding what makes certain glass safe for ovens and microwaves helps prevent dangerous shattering incidents.

Different materials like borosilicate and tempered glass respond differently to heat, making some suitable for baking while others crack under temperature changes.

This guide explains the science behind heat-resistant glass, compares material types, identifies trusted brands, and outlines proper usage to keep your kitchen safe.

Whether you’re baking casseroles or reheating leftovers, knowing which glassware to use matters.

The right knowledge prevents accidents and extends the life of your cookware.

What Makes Glass Heat-Resistant?

Glass becomes heat-resistant through specific material compositions and manufacturing processes that control how it responds to temperature changes.

The ability to withstand heat depends on thermal expansion rates and chemical structure.

How heat changes the glass structure

When glass heats up, its molecular structure expands. Standard soda-lime glass expands significantly, creating internal tension.

Heat-resistant glass contains additives that stabilize the molecular network, preventing excessive expansion.

The low expansion coefficient in specialized glass means the material stays dimensionally stable even at high temperatures.

Boron oxide in borosilicate glass creates stronger bonds between silicon and oxygen atoms, making the structure more rigid and less prone to expansion-related stress.

Thermal expansion and stress

Thermal expansion occurs when different parts of glass heat unevenly, causing some areas to expand faster than others.

This creates internal stress that can exceed the glass’s breaking point. The coefficient of thermal expansion measures how much a material expands per degree of temperature increase.

Standard glass has a high coefficient, while heat-resistant glass has a low one, reducing stress during heating and cooling cycles.

Why do some glass handles heat better

Material composition determines heat tolerance. Borosilicate glass withstands thermal shock because it can withstand direct flame contact and contains 15% boron trioxide, drastically reducing expansion.

Tempered glass gains strength through controlled heating and rapid cooling, which creates surface compression.

However, this process doesn’t change expansion rates like chemical composition does, making tempered glass strong but still vulnerable to thermal shock compared to borosilicate alternatives.

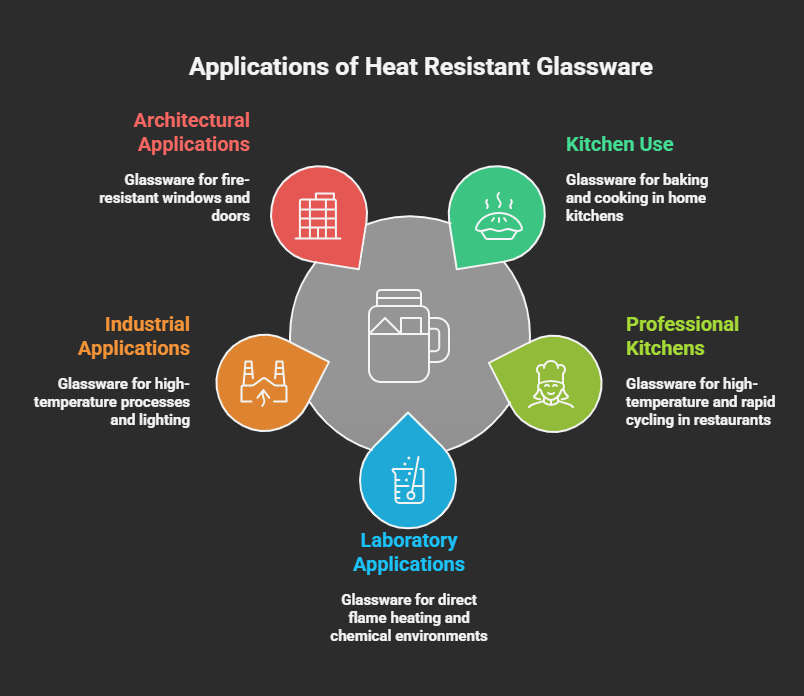

Types of Heat-Resistant Glassware

Different glass materials offer varying levels of heat resistance based on their chemical composition and manufacturing methods.

Understanding these distinctions helps you choose appropriate cookware.

1. Borosilicate Glass

Borosilicate glass represents the gold standard in heat-proof glassware due to its exceptional thermal shock resistance.

This material contains silica and boron trioxide, creating a structure that expands minimally when heated.

Originally used in laboratory settings, furnaces and kilns, it later became popular in cookware.

Older Pyrex manufactured in Europe still uses borosilicate, as do premium brands like Simax and OXO.

This glass tolerates temperature differentials of 330°F or more without cracking.

2. Tempered Glass

Tempered glass undergoes heat treatment that strengthens it mechanically but doesn’t improve thermal shock resistance significantly.

Most modern U.S. kitchen glassware, including brands like Corelle, Anchor Hocking, and current Pyrex products, uses tempered soda-lime glass.

While durable against impacts, this material shatters explosively when subjected to rapid temperature changes.

The tempering process creates internal tension that holds the glass together until a breaking point triggers complete disintegration into small, relatively harmless pieces.

3. Glass-Ceramic (Visionware type)

Glass ceramic material represents the most heat-stable option, capable of direct stovetop use.

Corning’s Visionware line exemplifies this rare category, featuring a crystalline microstructure that resists thermal shock exceptionally well.

Manufacturing involves controlled crystallization of glass, creating a hybrid material stronger than either component alone.

Though discontinued in many markets, vintage Visionware remains highly sought after.

This material withstands extreme temperature fluctuations and direct flame contact that would destroy conventional glassware.

4. Soda-Lime Glass (Non-Heat-Resistant)

Soda-lime glass makes up 90% of manufactured glass worldwide, used in drinking glasses, windows, and storage containers.

Composed primarily of silica, sodium carbonate, and lime, this economical material lacks heat resistance.

Understanding the mason jars’ heat-resistant status is crucial since these containers use soda-lime glass, unsuitable for oven use.

Sudden temperature changes cause immediate shattering. Never use decorative glassware, drinking glasses, or standard storage jars for heating applications.

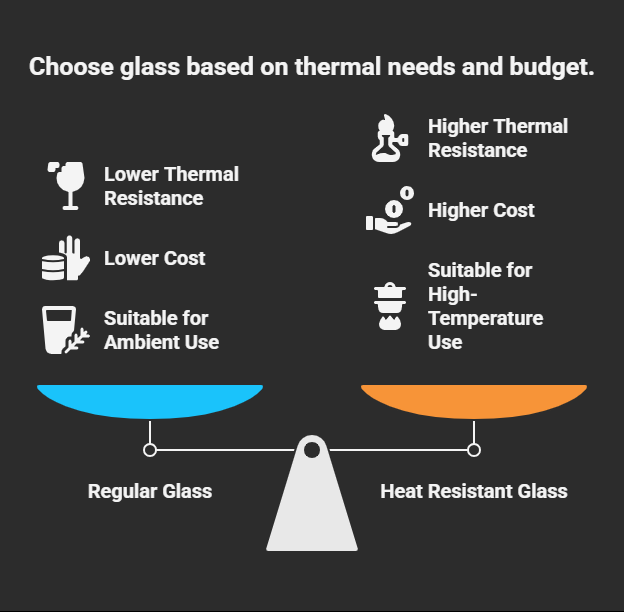

Heat-Resistant Glassware vs Regular Glass

The distinction between heat-resistant and regular glass lies in material science and thermal performance characteristics. These differences dramatically affect safety and usability.

How borosilicate behaves under heat

Borosilicate glass maintains structural integrity across extreme temperature ranges.

When heated, it expands approximately one-third as much as regular glass, preventing the internal stress that causes cracking.

You can transfer borosilicate directly from the freezer to the oven without risk.

Borosilicate glass brands like Simax and European Pyrex demonstrate this reliability consistently.

The material’s chemical stability also prevents leaching at high temperatures, maintaining food safety.

Why tempered glass shatters explosively

Tempered glass contains enormous internal stress from its manufacturing process.

Surface compression holds the glass together, but any breach releases this stored energy instantly.

When thermal shock creates a crack, the entire piece explodes into thousands of tiny cubes. This sudden failure mode differs from regular glass, which typically cracks progressively.

The explosive nature makes tempered glass unpredictable under thermal stress.

Common household items that are NOT oven-safe

Many everyday glass items lack heat resistance despite appearances. Drinking glasses, vases, picture frames, and decorative bowls use standard soda-lime glass.

Most glass food storage containers aren’t oven-safe unless explicitly labeled.

Wine glasses, stemware, and serving dishes typically shatter in ovens. Always verify manufacturer specifications before exposing any glass to heat.

Can Heat-Resistant Glassware Go in the Oven?

Oven safety depends on glass type, temperature limits, and proper usage techniques. Even heat-resistant glass has boundaries that shouldn’t be exceeded.

Oven-safe labels vs real safety

Manufacturer labeling indicates tested safety limits, but understanding what those labels mean matters.

“Oven-safe” typically means the glass withstands 350°F–450°F without preheating precautions.

However, labels don’t guarantee safety if you violate usage guidelines. Some FDA-approved food contact surface certified products still shatter when misused.

Always read specific temperature ratings and restrictions. European borosilicate pieces often tolerate higher temperatures than American tempered glass products.

Temperature limits

Borosilicate glass typically handles temperatures up to 450°F–500°F safely, while tempered soda-lime glass usually limits to 350°F–425°F.

Exceeding these thresholds risks structural failure. Oven safe fire king glass demonstrates reliable performance within the rated ranges.

Consider that oven hot spots may exceed the set temperature by 25°F–50°F. Glass-ceramic materials withstand even higher temperatures, sometimes exceeding 650°F.

Always leave a safety margin below maximum ratings for longevity.

Why preheating and direct contact matter

Placing cold glass in a preheated oven creates immediate thermal shock as the bottom heats rapidly while the top remains cool.

This temperature gradient generates internal stress. Always start with room-temperature glassware and heat gradually.

Never place glass directly on oven floors or heating elements where concentrated heat creates localized stress. Use oven racks for even air circulation.

Similarly, avoid placing hot glass on cold or wet surfaces, which reverses the shock effect.

Can You Use Heat-Resistant Glassware on the Stovetop?

Stovetop use presents different challenges than oven use, with most heat-resistant glass unsuitable for direct flame or burner contact despite oven safety.

Most heat-resistant glass is NOT stovetop-safe

Even borosilicate glass that handles ovens excellently typically fails on stovetops.

The concentrated, uneven heat from burners creates localized hot spots that expand faster than surrounding glass, causing immediate shattering.

Libbey glassware confirmed products are oven-safe, but explicitly warn against stovetop use.

Electric coil burners, gas flames, and induction cooktops all generate heat patterns too intense for standard heat-resistant glass.

Manufacturers specifically prohibit this application for liability reasons.

Exceptions (glass-ceramic)

Glass-ceramic cookware represents the only glassware truly safe for stovetops.

Products like vintage Visionware contain crystalline structures that distribute heat rapidly enough to prevent dangerous thermal gradients.

These specialized pieces work on gas, electric, and some induction cooktops.

The Duralex glassware brand produces some tempered pieces, but even these aren’t stovetop-rated.

True glass-ceramic feels slightly textured compared to smooth borosilicate and often appears amber or opaque rather than clear.

Risks of direct flame exposure

Direct flame creates the most severe thermal stress possible. Gas burners concentrate 1,000°F+ temperatures on small contact points while surrounding areas remain much cooler.

This extreme differential shatters even quality borosilicate glass within seconds.

The American glassware brand Pyrex explicitly prohibits flame contact on all products.

Flames also heat glass faster than its internal structure can equilibrate, creating mechanical failure from expansion mismatches.

Only purpose-designed laboratory borosilicate or glass-ceramic withstands direct flame safely.

Why Heat-Resistant Glass Can Still Shatter

Even properly rated heat-resistant glass fails under certain conditions. Understanding failure mechanisms prevents dangerous situations and extends the cookware life.

Hidden chips and stress points

Microscopic damage invisible to the naked eye creates failure initiation points.

Chips along rims, scratches on surfaces, or internal fractures from previous thermal stress concentrate force during heating.

These defects propagate rapidly when temperature changes occur. Even minor dishwasher contact between items creates micro-fractures that accumulate over time.

Always inspect glassware carefully before heating, running fingers along edges to detect damage.

Cold-to-hot transitions

Taking refrigerated or frozen glass directly to heat sources causes the most common failures.

The sudden temperature jump creates maximum internal stress as surface molecules expand while the core remains contracted.

This differential tears the material apart. Similarly, the Luminarc oven-safe brand recommends 15–30 minutes of room temperature equilibration before heating refrigerated glass.

Even heat-resistant glass needs gradual temperature transitions.

Uneven heating

Placing glass partially over burners, using high broiler settings, or creating air pockets under bakeware generates uneven heating that stresses glass unpredictably.

Filling the glass unevenly, so some areas heat faster than others, also creates problems.

Always ensure full, even support, and consistent food or liquid distribution.

Thick foods that insulate certain areas while others heat directly create differential expansion.

Sudden temperature changes (thermal shock)

Thermal shock occurs whenever temperature changes too rapidly for the glass structure to accommodate expansion or contraction.

Setting hot glass on wet counters, cold granite, or metal surfaces transfers heat quickly, shocking the material.

Adding cold ingredients to hot glass dishes mid-cooking creates similar stress.

The transition speed matters more than absolute temperature differences. Gradual changes allow molecular adjustment.

Best Uses for Heat-Resistant Glassware

Proper applications maximize safety and performance while leveraging the unique advantages of heat-resistant glass in cooking and food preparation.

Oven baking

Heat-resistant glass excels at oven baking between 300°F and 425°F. The transparency lets you monitor browning and doneness visually.

Glass conducts heat efficiently, creating evenly browned edges on casseroles and baked dishes. It retains heat longer than metal, keeping food warm at the table.

Reduce recipe temperatures by 25°F when converting from metal pans, since glass cooks slightly hotter. Avoid broiling functions that create extreme, uneven heat.

Microwaving

Glass provides the safest microwave option, creating no hot spots or chemical interactions.

Unlike plastic that may leach chemicals when heated, glass remains inert. The transparency reveals food during cooking without opening doors.

Use only microwave-safe, labeled glassware since some decorative glass contains metallic elements.

Never microwave an empty glass, as concentrated microwave energy without food to absorb it may stress the material.

Heating liquids safely

Glass allows visible monitoring of boiling liquids, preventing overflows and burns. The smooth, non-reactive surface doesn’t impart flavors or harbor bacteria like some plastics.

Heat-resistant measuring cups with handles facilitate safe pouring of hot liquids. Always leave expansion space at the tops of containers since liquids expand when heated.

Avoid superheating water in microwaves, which can erupt violently when disturbed.

Casseroles and roasting

Large baking dishes showcase glass’s advantages for one-dish meals. Even heat distribution prevents burnt edges while centers remain undercooked.

The material transitions from oven to table attractively for serving. Glass doesn’t react with acidic ingredients like tomatoes or citrus that might affect metal pans.

However, avoid overcrowding ovens since restricted airflow creates uneven heating that stresses glass.

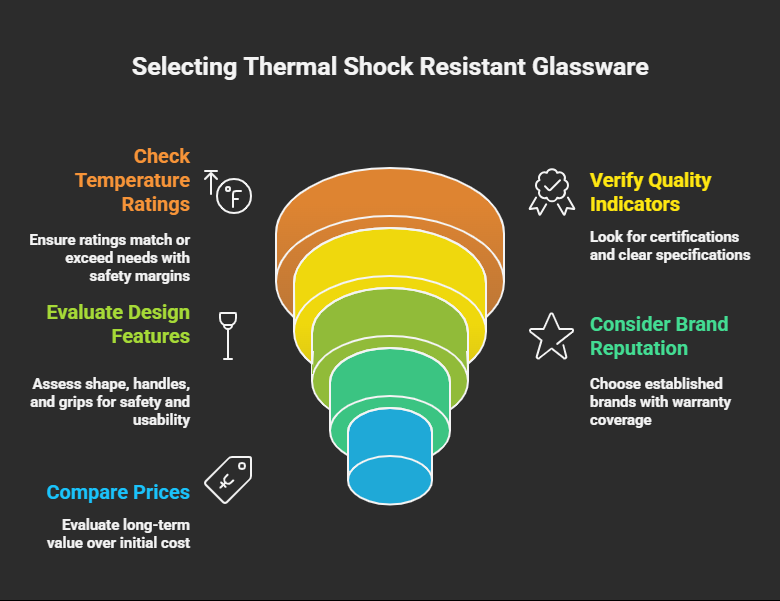

Top Brands of Heat-Resistant Glassware

Brand selection affects safety, durability, and performance. Manufacturing standards and material choices vary significantly between producers.

Pyrex (USA vs International differences)

Pyrex represents the most recognized heat-resistant glass brand, but its composition varies by region.

European Pyrex still uses borosilicate glass, offering superior thermal shock resistance.

American Pyrex switched to tempered soda-lime glass in 1998, reducing manufacturing costs but increasing shatter risk.

European versions tolerate more extreme temperature changes and higher absolute temperatures.

Check the manufacturing location when purchasing, as “Pyrex” doesn’t guarantee the material type.

Anchor Hocking

This American manufacturer produces affordable tempered glass bakeware sold widely in U.S. stores.

While not borosilicate, their products meet safety standards for typical oven use when properly handled.

The brand’s Fire-King line includes some vintage borosilicate pieces, though modern production uses tempered glass.

Anchor Hocking clearly labels temperature limits and usage restrictions. Their products perform reliably within stated parameters but require careful thermal shock avoidance.

OXO borosilicate

OXO entered the heat-resistant glassware market with borosilicate measuring cups and storage containers.

These products offer European Pyrex-equivalent thermal shock resistance at competitive prices.

The clear labeling helps consumers identify true borosilicate versus tempered glass. Ergonomic handles and measurement markings add functionality.

OXO’s commitment to borosilicate gives American consumers access to superior thermal performance without importing European products.

Simax & Duralex

Simax manufactures Czech borosilicate glassware with exceptional heat resistance, widely available online.

Their laboratory-grade composition handles extreme temperatures reliably.

Duralex produces French tempered glass known for mechanical strength rather than thermal shock resistance.

Both brands ship internationally, though breakage during shipping remains a concern.

Simax represents the best choice for consumers prioritizing thermal performance, while Duralex excels in impact resistance for everyday tableware.

Safety Precautions When Using Heat-Resistant Glass

Following proper protocols prevents most glass failure incidents. These practices apply regardless of glass type or brand.

Avoid cold-to-hot shocks

Always bring refrigerated or frozen glass to room temperature before heating. Wait at least 15 minutes for equilibration.

Never place frozen glass in ovens or microwaves directly. Similarly, don’t add frozen ingredients to hot glass dishes during cooking.

The thermal gradient from sudden temperature changes exceeds even borosilicate’s tolerance. Plan to allow proper temperature transitions.

Do not place hot glass on cold surfaces

Setting hot glassware on granite counters, metal trivets, or wet surfaces causes reverse thermal shock as heat rapidly exits the glass.

Use dry wooden cutting boards, silicone mats, or folded kitchen towels as landing pads. Avoid running cold water over hot glass when washing.

Let the pieces cool gradually at room temperature first. This precaution matters as much as avoiding cold-to-hot transitions.

Inspect for chips or cracks

Run your fingers along all edges and examine surfaces in bright light before each use. Any damage, no matter how minor, can propagate catastrophically during heating.

Chips concentrate stress, initiating cracks that spread instantly.

Discard compromised pieces immediately, regardless of sentimental value. The risk of explosive failure and potential injury outweighs any economic consideration.

Follow the manufacturer’s heat limits

Never exceed stated temperature maximums even if the glass appears fine at higher temperatures.

Repeated exposure beyond ratings causes cumulative damage that eventually triggers failure. Read the instructions and save them for reference.

Different pieces from the same brand may have different ratings. When in doubt, limit temperatures to 350°F and avoid thermal shocks completely.

Heat-Resistant Glass vs Ceramic Cookware

Comparing glass and ceramic helps determine which material suits specific cooking needs better. Each offers distinct advantages and limitations.

Heat tolerance differences

Ceramic cookware generally tolerates higher absolute temperatures than glass, often rated to 500°F–550°F.

Stoneware and porcelain handle broilers better than glass. However, quality borosilicate glass resists thermal shock more effectively than many ceramics, which can crack from rapid temperature changes despite high ratings.

Ceramic absorbs and releases heat more slowly, affecting cooking times. Glass heats faster but also cools faster.

Which is more durable?

Ceramic withstands physical impacts better than glass, rarely shattering from drops.

Chips in ceramic typically don’t propagate like glass fractures. However, glazes can craze or crack over time, creating sanitation concerns.

Glass maintains its surface integrity longer, but shatters completely when broken.

For longevity under normal use, quality ceramic often outlasts glass, especially in households with handling accidents.

Which is better for non-toxic cooking?

Both glass and ceramic offer non-toxic cooking when properly manufactured.

Glass provides inherent chemical inertness, never leaching substances into food. Ceramics’ safety depends on glaze composition, with some containing lead or cadmium.

Modern ceramics from reputable manufacturers meet safety standards, but vintage or imported pieces require caution. Glass provides more consistent safety assurance across all products.

Safer Alternatives to Heat-Resistant Glass

When glass doesn’t suit your needs, several alternatives provide excellent heat resistance with different performance characteristics.

Stoneware

Unglazed or naturally glazed stoneware offers excellent heat retention and distribution. The porous ceramic material withstands temperatures up to 450°F–500°F reliably.

Stoneware develops non-stick properties over time through seasoning, reducing chemical coating needs.

The material transitions beautifully from oven to table. However, it’s heavier than glass and can crack from severe thermal shock, requiring similar precautions.

Stainless steel

Stainless steel provides virtually indestructible heat resistance for stovetop and oven use. The material tolerates any residential cooking temperature without degradation.

Unlike glass, metal handles thermal shock effortlessly and never shatters. Stainless steel won’t break if dropped and cleans easily.

However, opacity prevents visual monitoring during cooking, and reactive foods may pick up metallic tastes from lower-quality steel.

Porcelain bakeware

High-fire porcelain creates an elegant, heat-resistant option for baking between 400°F and 500°F.

The fine-grained ceramic resists staining and odor absorption better than earthenware.

Porcelain’s white surface beautifully presents food at the table. The material conducts heat more evenly than glass, preventing hot spots.

However, porcelain remains fragile and can chip or crack from impacts or extreme thermal shock.

Pure ceramic cookware

Modern ceramic cookware often refers to metal pans with ceramic non-stick coatings rather than solid ceramic.

These hybrid designs combine metal’s durability with ceramic’s non-stick properties.

True ceramic cookware made entirely from fired clay offers chemical-free cooking without coatings that degrade over time.

Both versions handle high heat well, though coating durability varies by manufacturer quality.

FAQ — Heat-Resistant Glassware

Can heat-resistant glass break?

Yes, even heat-resistant glass breaks under certain conditions.

Thermal shock from rapid temperature changes, hidden chips or cracks, uneven heating, and exceeding temperature limits all cause failure.

Borosilicate resists breaking better than tempered glass, but neither is indestructible.

Proper handling and gradual temperature transitions prevent most breakage incidents when using quality heat-resistant glassware.

Can you microwave all glass?

No, only microwave-safe glass should be heated in microwaves. Standard drinking glasses, decorative glass, and some storage containers lack heat resistance.

Some glass contains metallic elements that spark dangerously. Always check for microwave-safe labels before use.

Heat-resistant glass, like borosilicate, handles microwaving excellently, but ensure your specific piece has proper certification before heating.

Is Pyrex still borosilicate?

American Pyrex switched from borosilicate to tempered soda-lime glass in 1998. European Pyrex, manufactured by Arc International, still uses borosilicate composition, offering superior thermal shock resistance.

Check the manufacturing origin when purchasing, as the brand name alone doesn’t indicate material.

Vintage American Pyrex from before 1998 contains borosilicate and performs better than modern U.S. versions.

What is the safest type of glass for the oven?

Borosilicate glass provides the safest oven option due to exceptional thermal shock resistance and high temperature tolerance.

This material handles temperature differentials and gradual heating better than alternatives.

Glass-ceramic offers even better performance but remains rare in consumer markets.

When borosilicate isn’t available, properly labeled tempered glass works safely if you follow temperature limits and avoid thermal shocks.

Final Summary — Heat-Resistant Glassware Is Safe When Used Correctly

Heat-resistant glassware serves kitchens reliably when matched to appropriate applications and handled properly.

Understanding material differences between borosilicate, tempered glass, and glass-ceramic helps you choose the right tool for each task.

European borosilicate offers superior thermal shock resistance compared to American tempered glass, though both work safely within their limitations.

Always verify manufacturer specifications, inspect for damage before use, and avoid extreme temperature transitions.

Never use stovetops unless specifically designed for it, and respect temperature maximums regardless of glass type.

While heat-resistant glass can shatter under certain conditions, following proper protocols prevents most failures.

The transparency, chemical inertness, and even heating make glass an excellent choice for baking, microwaving, and food storage when you understand its boundaries.